CX-40MW computer metallographic microscope is a three-eye upright metallographic microscope, which has excellent imaging performance and comfortable operating experience, providing customers with cost-effective solutions for metallographic analysis and industrial testing.

CX-40MW computer metallographic microscope is a three-eye upright metallographic microscope, which has excellent imaging performance and comfortable operating experience, providing customers with cost-effective solutions for metallographic analysis and industrial testing.

Observation Tube

The observation cylinder with the best comfortable Angle (30°) of the newborn bed can relieve the tension and fatigue of the user in the long-term working state and ensure the best observation state. Observe the scale on the cylinder, convenient for users to adjust the best pupil distance range.

Falling Illuminator

Cora lighting system with field stop, aperture stop and oblique lighting device; Preset polarizer, polarizer and filter slots.

A single 5W LED warm white light (3000-3300K), compared with similar LED lighting, can minimize the visual fatigue of the observer.

The field of view diaphragm and aperture diaphragm adopt a pull rod device, the center is adjustable, and the size of the illumination range can be flexibly adjusted to effectively avoid the impact of stray light on the image.

Polarizer and polarizer can achieve easy polarizing observation, you can also choose different color filters according to your needs to obtain the ideal observation effect.

CX-40MW Computer Metallographic microscope Configuration table:

| Standard Configuration System | Model | |

| Component | Specification | CX-40MW |

| Optical System | Infinite distance color correction optical system |

· |

| Observation Cylinder | 30° tilt, hinged triocular observation cylinder, 360° rotation; Pupil distance adjustment: 54mm~75mm, unilateral visibility adjustment: ±5 diopter, two spectral ratios, binocular: three eyes = 100:0, 50:50 |

· |

| Eyepiece | High eye point large field of view flat field eyepiece PL10X/22mm |

· |

| An achromatic objective with an infinitely long anomaly field | LMPL 5X /0.15 WD10.8mm |

· |

| LMPL 10X/0.30 WD12.2mm |

· |

|

| LMPL 20X/0.45 WD4.00mm |

· |

|

| LMPL 50X/0.55 WD7.9mm |

· |

|

| Converter | Internal positioning five-hole converter |

· |

| Focusing Mechanism | Reflection frame, low hand position coarse micro coaxial focusing mechanism, coarse adjustment stroke 28mm, fine tuning accuracy 0.002mm. It is provided with an adjusting elastic device to prevent sliding and a random upper limit device. With platform position up and down adjustment mechanism, maximum sample height 78mm. |

· |

| The stage | Double-layer mechanical moving platform, low hand position X, Y direction coaxial adjustment; Platform area 175X145mm, moving range: 76X42mm can be equipped with dual-purpose glass plate. |

· |

| On the lighting system | Adaptive wide voltage 100V-240V_AC50/60Hz, reflection lamp room, single high power 5WLED, warm color, Cora lighting, with field stop and aperture stop, center adjustable, with oblique lighting device |

· |

| Metallographic analysis system | FMIA2024 genuine metallurgical analysis software, 12 million SONY chip camera device, 0.5X adaptive mirror interface. Micrometer. |

· |

| Optional Configuration | ||

| Parts | Specifications |

O |

| Eyepiece | High eye point large field of view flat field eyepiece PL10X/22mm (adjustable viewing, with micrometer) |

O |

| High eye point large field of view flat field eyepiece PL15X/16mm |

O |

|

| Objective lens | Infinitely long anomaly field achromatic objective lens: LMPL 100X/ 0.80WD2.1mm |

O |

| Focusing mechanism | Transparent and reverse dual-purpose frame, low hand position coarse and micro coaxial focusing mechanism, coarse adjustment stroke 28mm, fine tuning accuracy 0.002mm. It is provided with an adjusting elastic device to prevent sliding and a random upper limit device. With platform position up and down adjustment mechanism, maximum sample height 28mm. |

O |

| Lower lighting system | Adaptive wide voltage 100V-240V_AC50/60Hz, spotlight room, single high-power 5WLED, warm color. |

O |

| A condenser | Transmission type roll-out achromatic condenser (N.A.0.9) with variable aperture stop and adjustable center. |

O |

| A color filter | Yellow, green contrast filter, neutral filter |

O |

Note: "·" is the standard configuration; "O" is an optional item

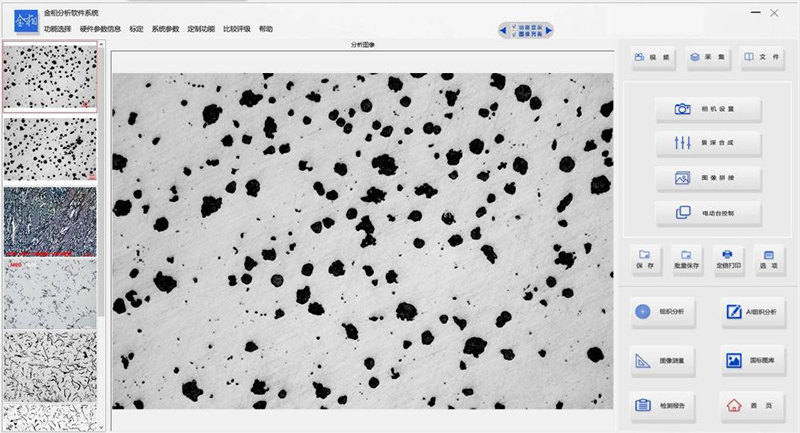

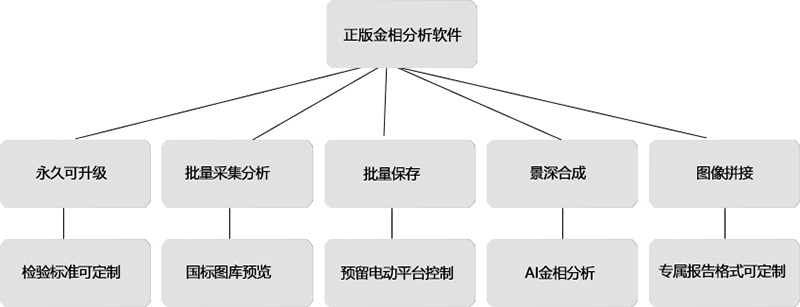

FMIA2024 genuine metallurgical image analysis software

FMIA2024 Metallographic image analysis software is based on the current needs of foundry enterprises, auto parts enterprises, heat treatment enterprises, bearing steel industry, power system industry, railway parts industry, and related testing companies for metallographic testing. In order to improve the product pass rate and help improve the laboratory inspection level, we collect the needs of experts and teachers in various industries. A new set of metallographic image analysis software system is developed.

The FMIA2024 version of metallographic image analysis software has been revised and upgraded. The system covers a large number of metallographic detection standards at home and abroad, integrates quantitative analysis and qualitative analysis, adds depth of field synthesis function and image field splicing function, and has a simple interface, which allows continuous shooting of multi-field images and centralized image organization analysis, making operation more convenient. Eliminate all kinds of complicated steps of the previous software, so that the detection is faster and more efficient.

A new set of "professional - accurate - efficient" metallographic analysis tool system is created to simplify metallographic analysis.

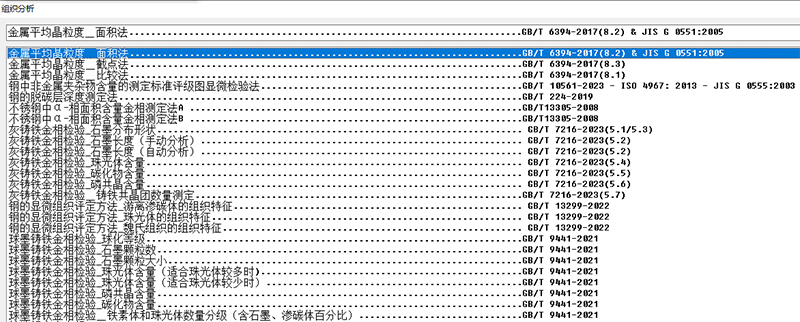

The national standard library of the software system contains hundreds of categories, basically covering the commonly used metallographic standards, and adapting to the requirements of metallographic analysis and inspection of the vast majority of units. According to the needs of different industries, relevant categories are designated and opened to meet the requirements of industry testing. Free access to all modules for life, free upgrade standards for life.

In view of the increasing number of new materials and imported materials, materials and assessment standards that have not been entered in the software can be customized and entered separately.

FMIA2024 Metallographic image analysis software product advantages and functions:

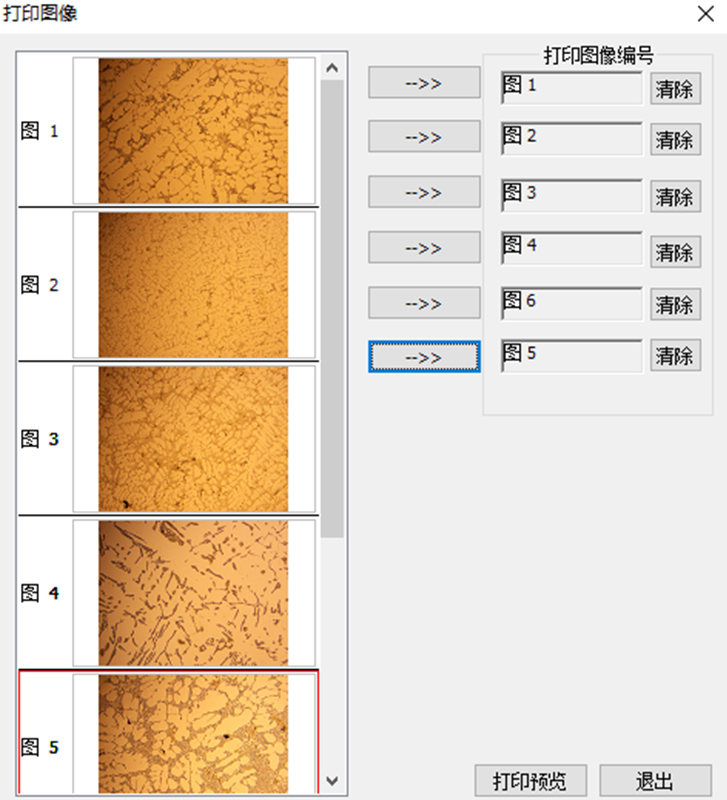

Batch shooting and archiving of video images: batch shooting, batch setting name, batch saving, batch printing and other multi-image batch processing functions make the batch sample inspection process more convenient and efficient.

Camera Settings: exposure time, gain, sharpness, saturation, gamma value, contrast, brightness, white balance, black balance and other function Settings.

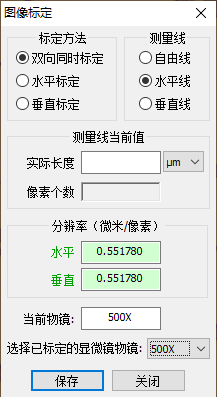

Image calibration: The calibration function is newly upgraded, and all objective parameter calibration is completed. Compared with the original calibration method, the new calibration method is more convenient and fast.

Image processing functions: color separation, gray conversion, threshold segmentation, binary processing, image enhancement, reverse phase adjustment, sharpening adjustment, scratches and smudges processing, image histogram, etc.

Printing function: multi-picture printing, custom picture name, scale parameter setting, export PDF/Word/Excel, print preview and other functions.

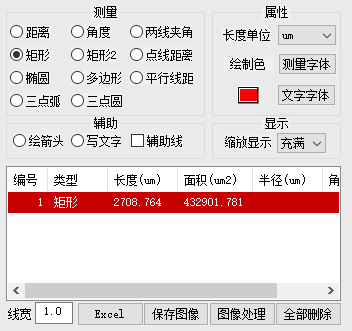

Image measurement and archiving: The variety of measurement tools (including distance, Angle, Angle between two lines, rectangle, point and line distance, ellipse, polygon, parallel line distance, three-point arc, three-point circle, etc.), can draw arrows, annotate text, add auxiliary lines, modify line width, length units of various options, measurement data font color, size, font style options, test data can be summarized and exported to Excel tables .

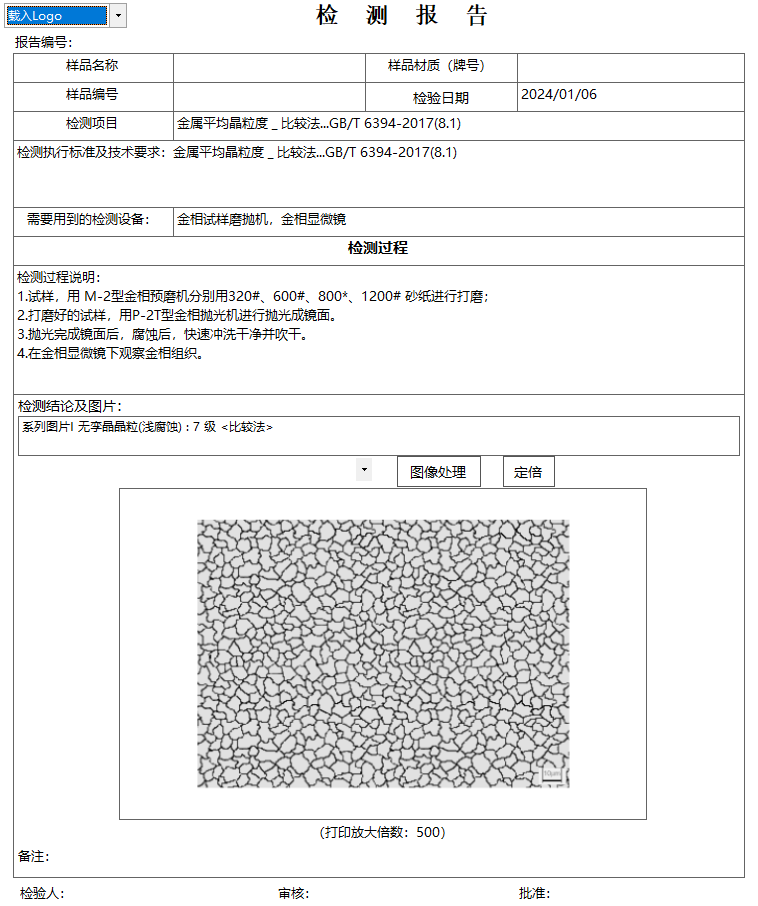

Tissue analysis functions: detection standard module library, diversification, contain GB/ASTM/ISO/DIN/QC/JB/DL/TB/SS standards organization analysis, software library of standard upgrade, can free upgrade the new standard, with automatic, comparison, auxiliary metallographic rating of three functions. Easy to use, simple and fast, accurate and reliable measurement.

Advanced function module: EDF depth of field extension function, image stitching function

Advanced customization functions: customized microscope electric table control function, image confocal, 3D light map, image database, etc.

AI organization analysis function: The AI organization analysis module can be customized, and artificial intelligence can be used to complete the entire microstructure analysis and detection process, automatically identify the microstructure structure and analysis of materials, and the operation process is simple, reducing the labor intensity of personnel and improving the efficiency of material detection.

National standard map library: contains 100 kinds of national map, for customers to learn reference.

Diversified report templates: Automatically generate an illustrated metallographic analysis report, with the option to generate a single or multi-module report style. The report template can be modified to add the enterprise logo, company name, and detection process. Customized report templates are available.

FMIA2024 metallurgical analysis software system composition:

1. Software program FMIA2024 (U disk);

2. Encryption lock: USB + dynamic code verification;

3. Text materials: "Instruction manual" (on the U disk);

4. Microscale: grid value 0.01mm.

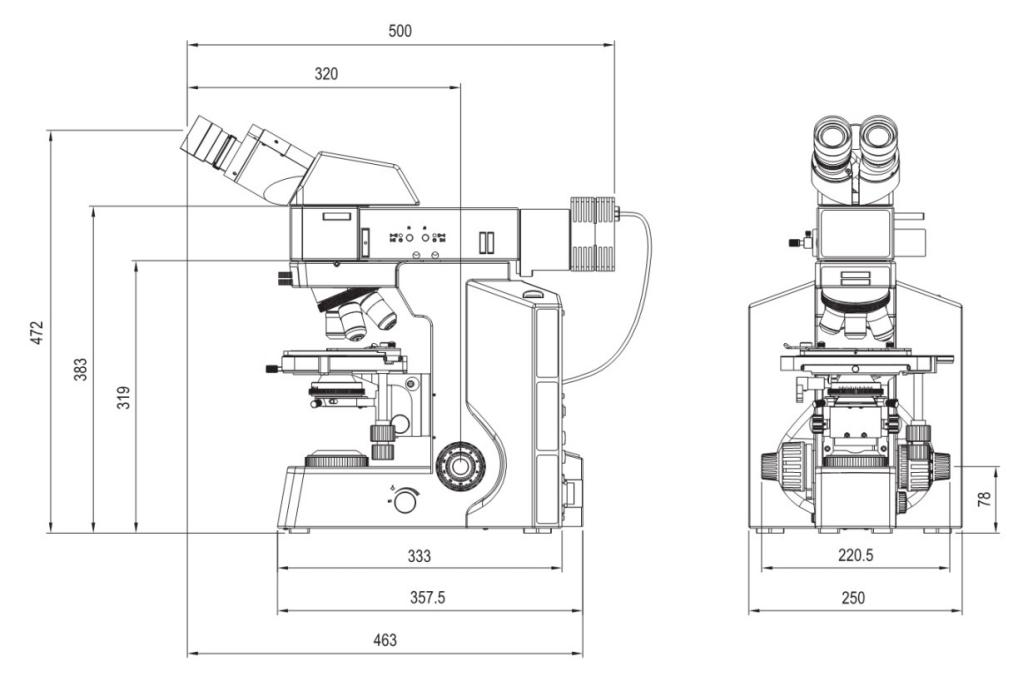

CX-40M upright Metallographic microscope size: