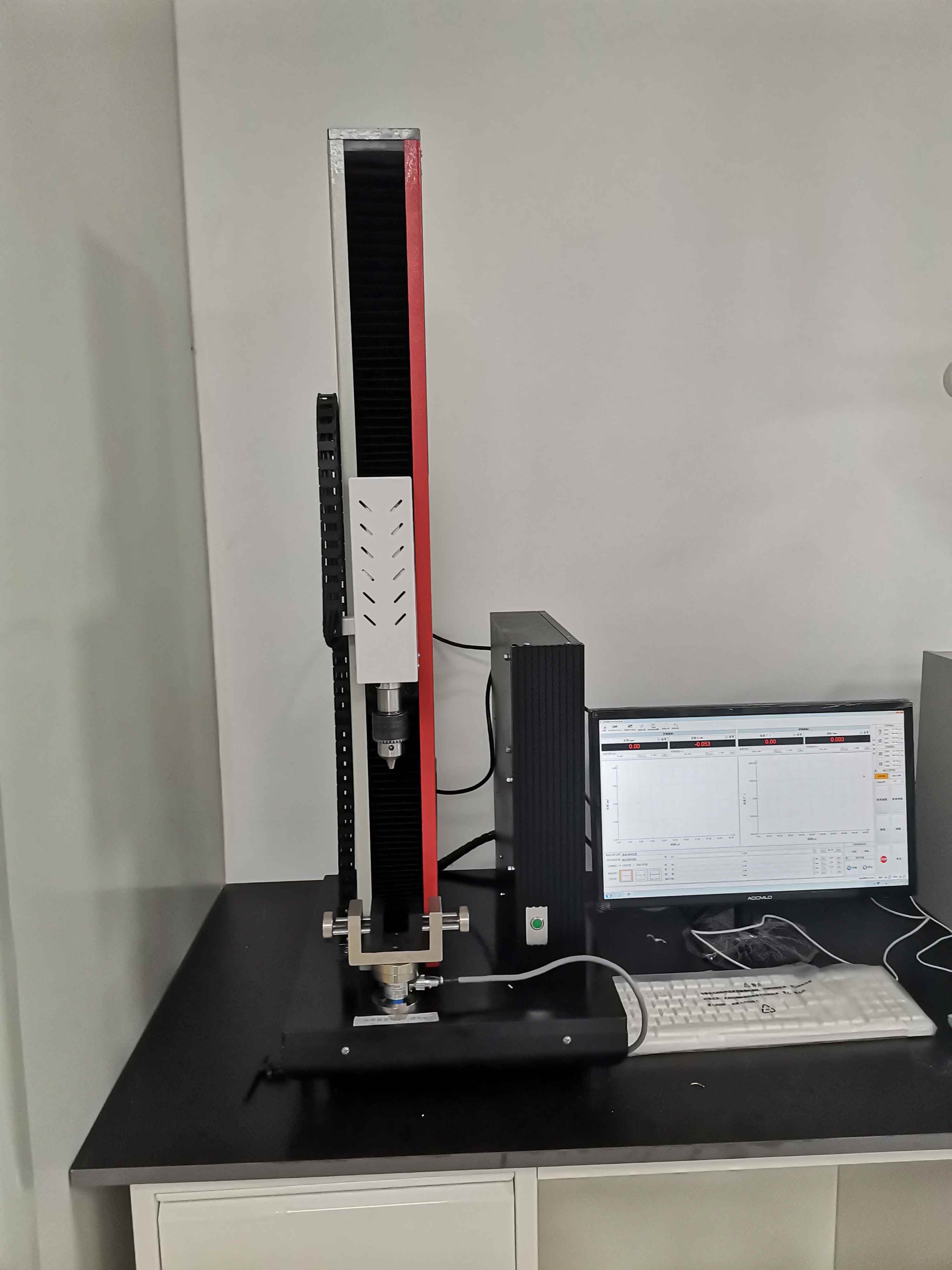

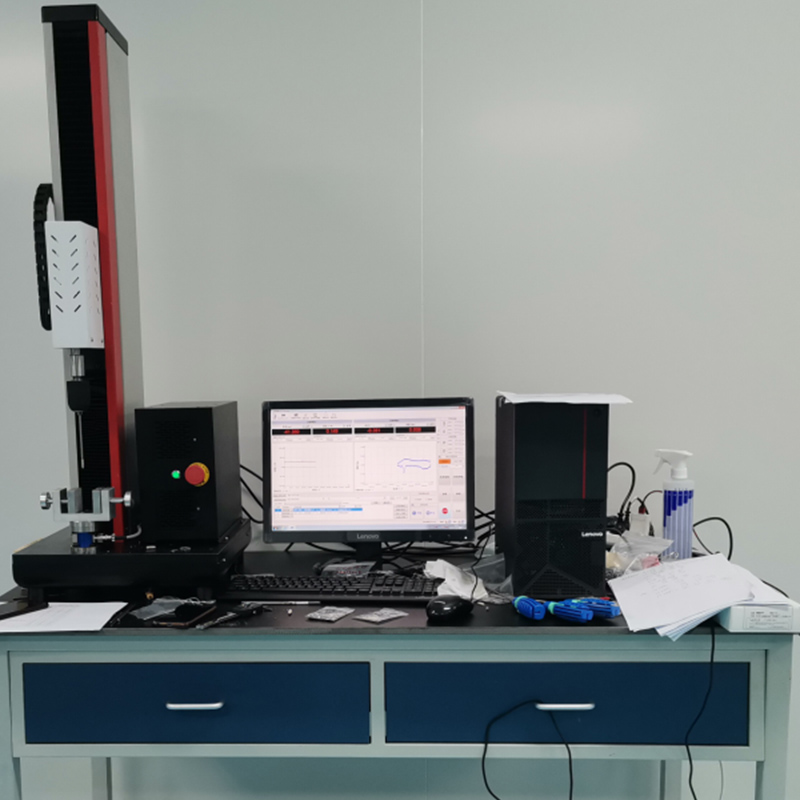

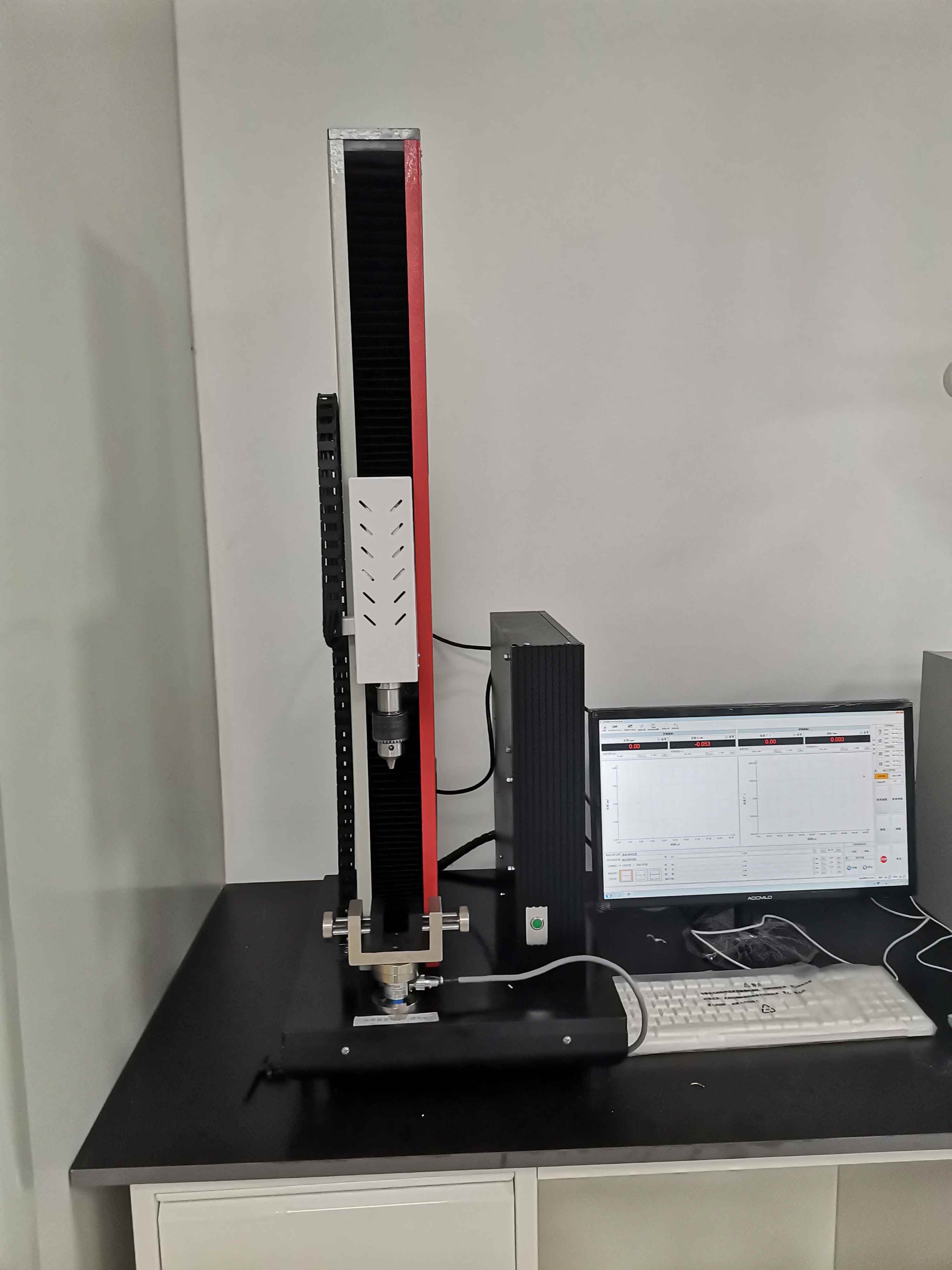

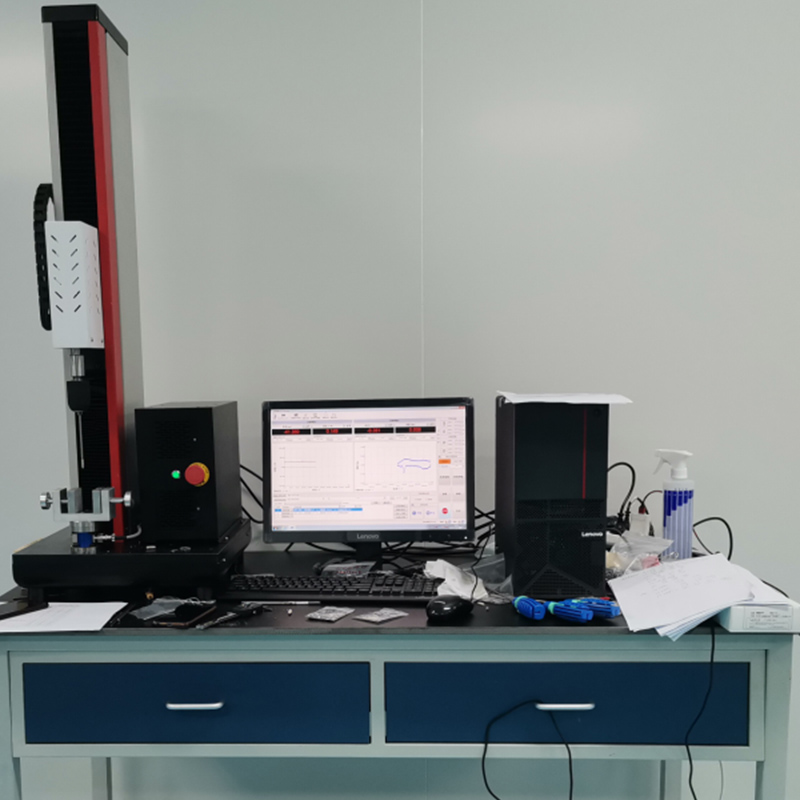

Vertical bone screw torsion comprehensive performance testing machine

Bone screw rotary torque tester

Bone screw axial pull-out and torsion screwing machine Product introduction:

Bone pins are commonly used in surgery for implant fixation, bone attachment devices, or internal fixation plates of the skeletal system. In conventional clinical practice, when bone pins are placed in the body, they are subjected to axial and torsion forces applied by the surgeon. Manufacturers and scientists evaluate new materials and designs for bone pins by testing their various mechanical properties.

Standard ASTM F543-07 Test A4, "Test Method for Self-tapping Medical Bone Nails", specifies the method for evaluating the axial force required for a self-tapping bone nail to drill into standard experimental material. Although it is considered a simple procedure clinically, it is a relatively complex motion to reproduce in vitro due to the interaction of the rotary and linear axes of the testing machine. The test required a continuous rotation speed of up to 30rpm, while the axial load gradually increased at a loading rate of 2N/s while the drill was drilled. The purpose of this test was to record the torque curve of the bone screw when it was drilled into and removed from the material

Important functions of bone screw axial removal and torsion screwing testing machine:

The bone screw axial pull-out and torsional screw-in tester is used to measure the Z large breaking torque and breaking torque Angle of metal bone screws.

Fixture: bone screw test fixture should be customized according to customer products according to the type of sample, the front end uses a special chuck to grip the outer circle of the sample, and the back end design fixture tip rod shape is consistent with the center hole of the sample (equipped with non-standard chuck tooling); Adjust the position of the moving seat so that the top rod of the fixture and the sample are completely inserted and aligned, and then the program can be edited to start the test to obtain the required torque. According to the type and size of the sample, different size specifications of the fixture top rod are designed.

→ Used for testing and studying the torque performance of bone screws, fracture torsion Angle of bone screws, axial pressure performance of bone screws (metal bone screws, absorbable bone screws, self-tapping bone screws, intramedullary screws, etc.).

→ Torque performance testing and research of different thread types of bone screws (deep thread and shallow thread, full thread and half thread, symmetric and mismatched thread).

→ Torque performance test and research of bone screws with different thread codes and nominal diameters (HA/HB/HC/HD1.5-8.0mm).

→ Test and study on the moment performance of bone screws for different purposes (cortical bone screws, cancellous bone screws, V-shaped intramedullary screws, trilobated intramedullary screws, hollow screws).

→ Moment performance test and research of different screw rotation forms (single slot, cross slot, hex, square slot, inner triangle, club shape).

→ Moment performance test and research of different head types of bone screws (conical head, spherical head, semi-circular head, square head).

→ Testing and research on torque performance of bone screws of different materials (stainless steel bone screws, absorbable bone screws, poly-crossester copolymer, L-Lactide resin, ethyl crossester resin, L-lactic acid resin, rigid polyurethane foam, hydrolytically degradable polymer resin, copolymer).

Important features of bone screw axial removal and torsion screwing testing machine:

→ Ergonomic design, suitable for people, people adapt to the machine, in line with the man-machine-environment system, efficient, healthy, comfortable and safe.

→ High rigidity, high stability, no vibration impact, streamlined load frame, frame size can be customized.

→ High precision symmetrical torque sensor, linear width, good stability, to ensure the test accuracy of torque load.

→ High speed, low vibration, maintenance-free, silent AC servo motor drive system.

→ Built-in Ethernet interface; Stop and go function; Flexible operation and free switching.

→ The circuit board adopts photoelectric isolation design, strong anti-interference ability.

→ With a variety of perfect test fixtures, quick replacement; Optional environmental systems and strain torsiometers.

→ Wide torsion test speed, optional from 1r/min to 30r/min.

→ Built-in full digital closed loop, multi-channel, multi-function, easy to control Bab103 torsion test measurement and control software; A variety of standard methods (national standard, national military standard, British standard, American standard, German standard, Japanese standard, Italian standard, Russian standard, French standard, Australian standard, European standard /GB, GJB, ISO, JIS, ASTM, DIN, BS, NF, EN, AS, NBR, IEC, GOST, CNS).

→ Torque load automatic control, automatic hold, cycle control and self-programming control and other control methods.

→Z high torque and Z high break torsion Angle test, screwing torque test, bone screw fracture position test, bone screw torsion yield strength test.

→ Automatic tracking and measurement of torque and torsion Angle, real-time display of test curve, torque value, torsion Angle, torsion speed.

→ Automatic control of the test process, full closed-loop control of torque, stress, deformation, torsion Angle, display, full keyboard input operation and control mode intelligent setting system.

→ Intelligent setting of control mode, no impact between control modes, smooth switching, smooth loading and unloading.

→ Process reproduction and data reanalysis, curve amplification, comparison, traversal, curve can be freely enlarged and reduced.

→ Multiple curves are displayed at the same time (torque-time curve, torque-twist Angle curve, angle-time curve, etc.), coordinates are self-set, full degree self-adjustment.

→ Control software, modular, open programming, personalized design, can be adjusted.

→ Standard module: rights management module, test module, control module, analysis module, query module, output module, etc.

→ Flexible Excel or Word report format, you can select, specify, sort, separate, merge, multiple types of output.

→ Operation prompts and wizard functions.

→ Network database management, can be directly connected with a number of networking companies.

→ Automatic return at the end of the test, intelligent, efficient and fast.

→ Multiple protection functions: overload protection of test force; Over-current and over-voltage protection; Safety protection when the sample is broken; Operation prompt wizard protection; Automatic protection after the test.

Contact us for more information on bone screw axial pull-out and torsional drive testing machines.

English

English

Español

Español

Português

Português

русский

русский

français

français

日本語

日本語

Deutsch

Deutsch

Italiano

Italiano

Nederlands

Nederlands

ไทย

ไทย

Polski

Polski

한국어

한국어

Svenska

Svenska

magyar

magyar

Malay

Malay

বাংলা

বাংলা

Dansk

Dansk

Suomi

Suomi

Pilipino

Pilipino

Gaeilge

Gaeilge

عربى

عربى

norsk

norsk

اردو

اردو

čeština

čeština

Ελληνικά

Ελληνικά

Українська

Українська

فارسی

فارسی

தமிழ்

தமிழ்

తెలుగు

తెలుగు

नेपाली

नेपाली

Burmese

Burmese

български

български

ລາວ

ລາວ

Latine

Latine

Қазақ

Қазақ

Euskal

Euskal

Azərbaycan

Azərbaycan

slovenský

slovenský

Македонски

Македонски

Lietuvos

Lietuvos

Eesti Keel

Eesti Keel

Română

Română

Slovenski

Slovenski

मराठी

मराठी

Српски

Српски

עִברִית

עִברִית

icelandic

icelandic

Беларус

Беларус

Монгол хэл

Монгол хэл

Javanese

Javanese