The machine is mainly used to measure the impact resistance of metal materials under dynamic load, so as to judge the properties of materials under dynamic load.

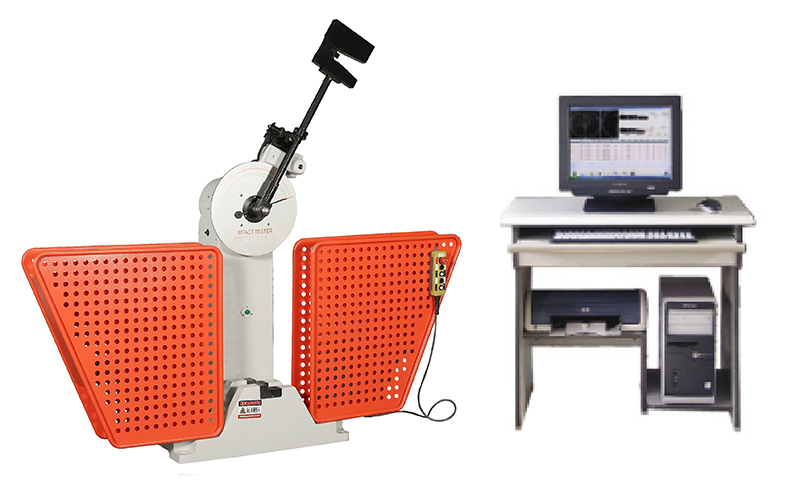

1. Equipment name: microcomputer screen display automatic impact testing machine

2. Model number: JBW-300B

3. Performance description:

The machine is mainly used to measure the impact resistance of metal materials under dynamic load, so as to judge the properties of materials under dynamic load.

The machine is a microcomputer screen explicit semi-automatic impact testing machine, using PC microcomputer control, electric swing, impact, microcomputer measurement, calculation, screen digital display results and can be printed, etc., high efficiency, high test accuracy. After the impact of the sample, the residual energy can be used to automatically swing, prepare for the next test, easy to operate, high efficiency. In the continuous impact test laboratory and a large number of impact tests of metallurgy, machinery manufacturing and other industries can reflect its superiority. The computer can calculate and digital display the impact absorption work, impact toughness, pendulum lifting Angle and test average value of the material, and can print the test data and test average value.

According to GB/T3808-2018 (test of pendulum impact testing machine) and ISO148-2(Metal materials pendulum Charpy impact test Part II), Testing machine verification), ASTM E23 related standards production and manufacturing in line with GB/T229-2020(metal Charpy notch impact test method), ISO148 (metal materials pendulum Charpy impact test), JJG 145-2007 (pendulum impact test regulations).

4. Main technical indicators:

1. Impact energy: 150J, 300J

2, pendulum prelift Angle: 150°

3. Distance from center of pendulum shaft to impact point: 750mm

4, impact speed: 5.2m/s

5. Span of sample support: 40mm

6, the mouth rounded corner: R1-1.5mm

7, impact blade rounded Angle: R2-2.5mm

8, impact knife thickness: 16mm

9, Angle accuracy: ±0.1°

10, sample size: 10×10×55mm

11. Overall size: 2124mm × 600mm × 1340mm

12. Net weight of testing machine: 450Kg

13, Power supply: AC three-phase 380V±10% 50HZ 5A

14, environmental conditions: no corrosive medium in the surrounding environment, no vibration, no strong electromagnetic field interference.

5. Main equipment configuration:

1, a 300 joule main machine;

2, 150J, 300J pendulum one each

3, take a set of pendulum transmission device (installed on the main engine)

4, a set of automatic hanging device (installed on the main engine)

5, a set of insurance institutions (installed on the host)

6, a set of safety protection devices

7. A pendulum disassembler

8, a support adjuster

9, the sample to the center of one

10, Lenovo printer a set

11, a set of special measurement software

6. Measurement and control part:

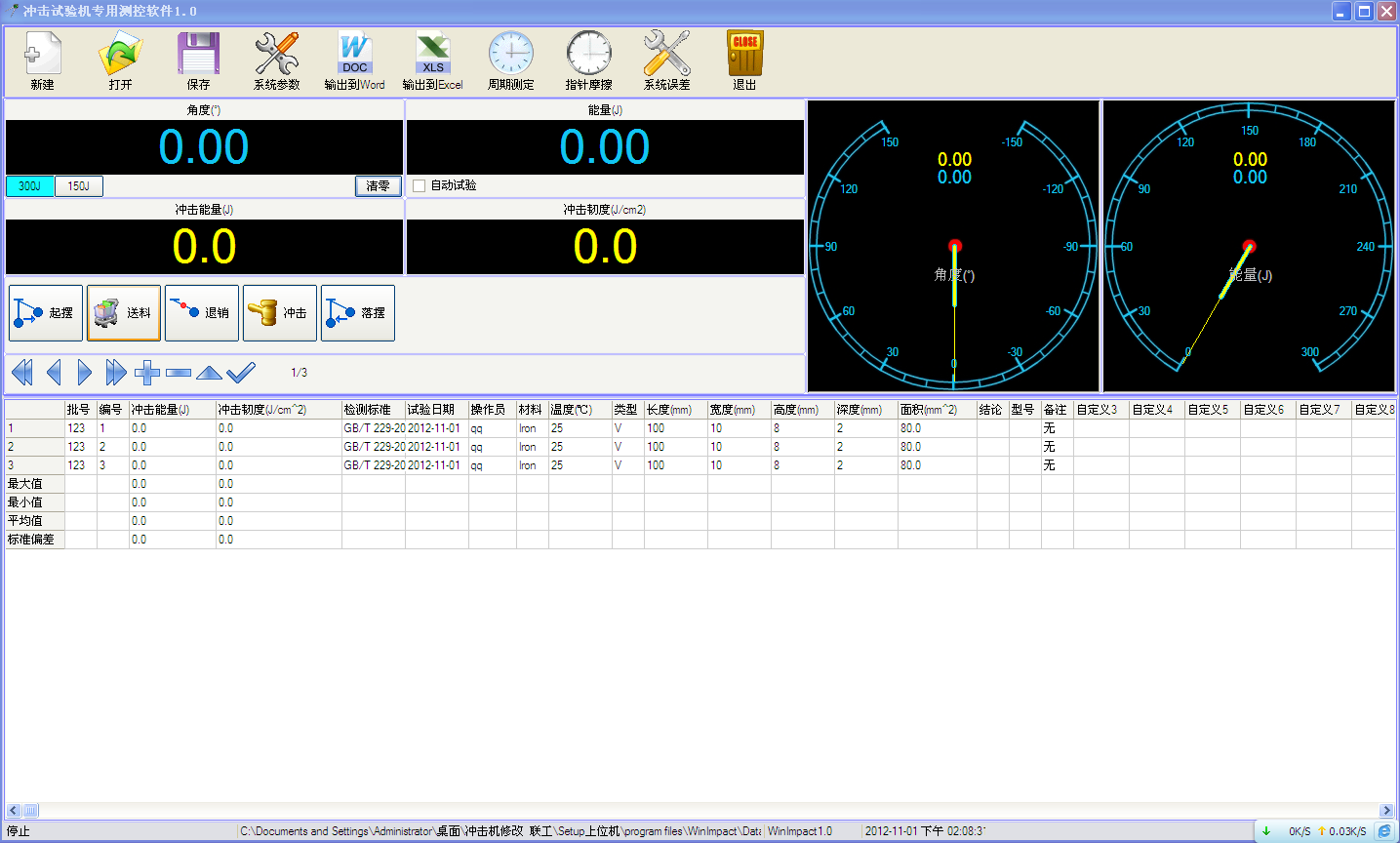

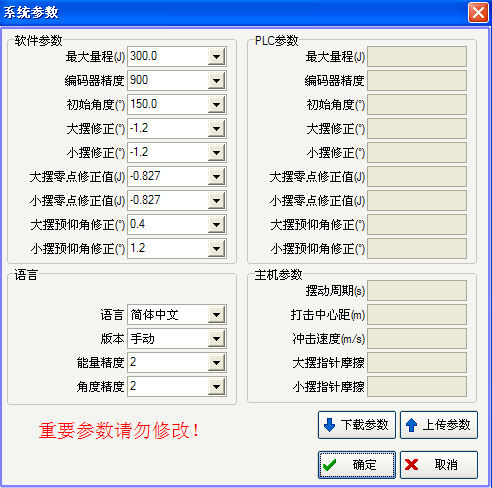

Windows platform, screen display, mouse operation (operation window is as follows);

To output lab reports, install Microsoft Word or Excel at least Office2003.

Software supports multiple pendulums.

Record impact strength, impact energy, etc. Maximum minimum mean and standard deviation can also be calculated.

Experimental results are calculated automatically. Automatic measurement of swing period

Experimental results can be based on customer requirements, provide communication protocols, meet the data upload, to achieve third-party remote monitoring.

Adhesive Stripping 90 Degree Stripping Testing Machine

Adhesive Stripping 90 Degree Stripping Testing Machine

Wire Twisting And Winding Integrated Machine

Wire Twisting And Winding Integrated Machine

Adhesive 90-Degree Peel Strength Testing Machine

Adhesive 90-Degree Peel Strength Testing Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

CPU-1020 Cup Convex Testing Machine

CPU-1020 Cup Convex Testing Machine