The GW-65 steel pipe bending tester is a special equipment for plane bending test of metal pipes. The equipment is a new product developed according to GB/T244-1997 ISO8491:1986 (E) "Bending test method for metal pipes".

Product introduction

Model: GGW-W

Processing customization: Yes

Weight: 1500

Measuring range: Φ15-φ65mm

Dimensions: 1410×900×1150

Microcomputer controlled steel pipe bending testing machine introduction:

The GW-65 steel pipe bending tester is a special equipment for plane bending test of metal pipes. The equipment is a new product developed according to GB/T244-1997 ISO8491:1986 (E) "Bending test method for metal pipes". The product is widely used in metal pipe factories and pipe enterprises to test the bending properties of metal pipes.

GGW-65 steel tube bending testing machine is a product developed on the basis of GW-40C steel bar bending testing machine. The equipment has reliable accuracy, easy to use, reliable limit and long service life. It is the most perfect bending testing machine at present.

Microcomputer controlled steel pipe bending testing machine Product features:

1, the vertical structure, bending experiment on the workbench operation, the operation method is fast.

2, the bending support point and front end adjustment distance is large, equipped with reverse bending head, can carry out reverse bending experiment.

3, compact structure, strong steel, adjust the screw is placed on the back side of the support slide groove to prevent the oxidation skin from falling into the damage of the screw.

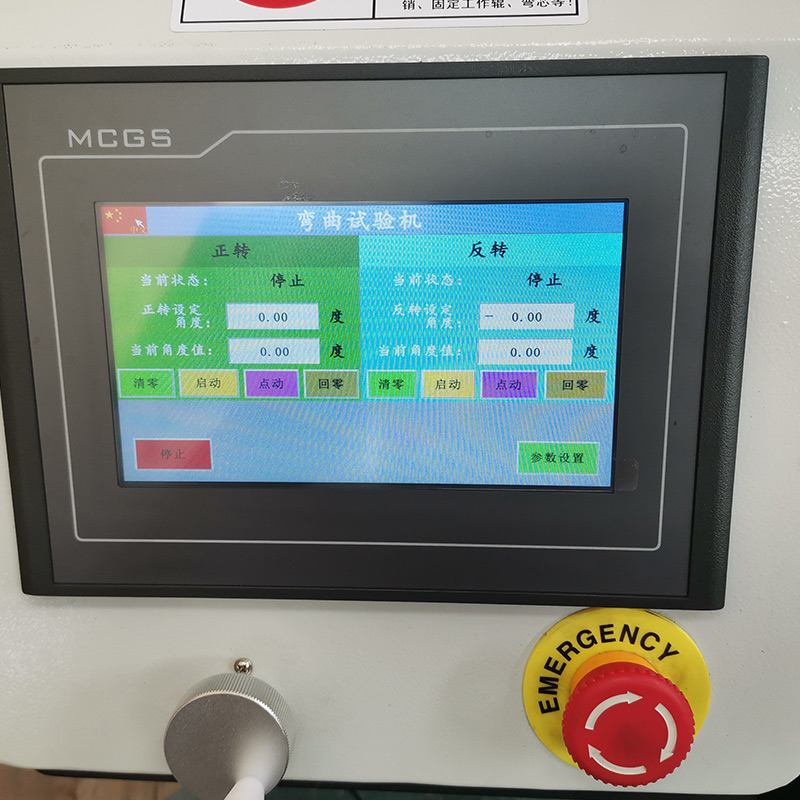

4, the use of photoelectric encoder Angle display and control, display accurate and reliable. And the front part of the experimental bench is provided with an Angle disk indicating device, and the machine has a double display device for bending Angle.

5, the bending Angle in the control system is set arbitrarily, with high precision and convenient operation.

Technical parameters:

Bending metal pipe diameter range 40- 65

The positive bending Angle of the metal tube is arbitrarily set within 0°-180°

The reverse bending Angle of the metal tube is arbitrarily set within 0°-90°

Working disk speed <2r/min

Roll center distance 390mm

Working disc diameter 830mm

Motor power 3.0kw

Randomly equipped with a set of standard bending core (diameter 40-65)

Main machine dimensions (length × width × height) 1200×900×1190(mm)

The machine weighs 1600kg

How it works:

Electrical working principle: The electrical control principle of the testing machine (as shown in FIG. 1) is the use of digital integrated circuit, the bending Angle of the testing machine is obtained by the photoelectric pulse shaping frequency division on the high-speed shaft of the motor, the Angle count and continuous cumulative display, when the working disk of the testing machine is turned to the set Angle, the circuit control makes the brake motor power off and stop rotating. Microcomputer control of steel pipe bending testing machine which is good.

Product configuration:

1. Brake motor

2, cycloidal pin gear reducer

3. Work plate

4, pressing device

5. Rack

6. Workbench

7. Working shaft and bending sleeve

8. Electrical part

9. Software control system

10. Computer printer

Adhesive Stripping 90 Degree Stripping Testing Machine

Adhesive Stripping 90 Degree Stripping Testing Machine

Wire Twisting And Winding Integrated Machine

Wire Twisting And Winding Integrated Machine

Adhesive 90-Degree Peel Strength Testing Machine

Adhesive 90-Degree Peel Strength Testing Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

CPU-1020 Cup Convex Testing Machine

CPU-1020 Cup Convex Testing Machine