This series of electronic universal testing machine is a classic practical model developed by our company, and is also the mainstream model currently produced.

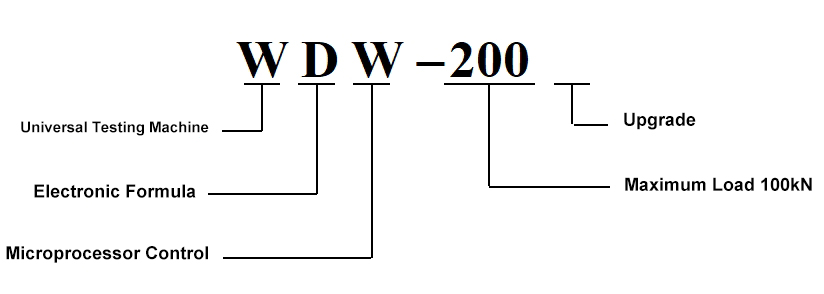

1. Specifications and models

2. Applicable standards:

GB/T 2611-2007 "Testing machine general technical requirements"

JB/T 7406.1-1994 Testing Machine Terminology Material Testing Machine

GB/T 16491-2008 "Electronic universal Testing Machine"

GB/T 16825.1-2008 "Testing of static uniaxial testing machines - Part 1: Testing and calibration of force measurement systems for tension and/or pressure testing machines"

GB/T 22066-2008 "Evaluation of Computer Data acquisition System for Static Uniaxial Testing Machine"

JJG 139-1999 "Tensile, Pressure and universal Material Testing Machine"

JB/T 6146-2007 "Extensometer Technical Conditions"

JB/T 6147-2007 "Testing machine packaging, packaging marks, storage and transportation technical requirements"

GB/T 228.1-2010 "Metal materials tensile test Part 1: room temperature test method"

GB/T 7314-2005 "Metal material compression test method at room temperature"

GB/T 232-2010 "Bending test Method for Metal Materials"

Other non-metallic test standards

3. Main technical parameters:

(1) Host parameters:

Number of columns: 6 columns (4 columns 2 screw);

Maximum stretching space (mm) : 600;

Maximum compression space (mm) : 600;

Maximum travel of moving beam (mm) : 1100;

Test width (mm) : 500;

Beam adjustment maximum speed (mm/min) : 600;

Column diameter (mm) : 55;

Screw specification: GD4005-5;

Table size (mm) Length × width: 500×280;

Worktable thickness (mm) : 100;

Upper beam thickness (mm) : 105;

Moving beam thickness (mm) : 105;

(2) Measurement parameters:

Maximum test force (kN) : 200;

Testing machine grade: 0.5;

Test force measurement range: 0.4% ~ 100%F.S (maximum load);

Test force measurement accuracy: better than the indicated value of ±0.5%;

The resolution of the test force: 1/500000 of the full scale (the full scale has only one resolution, without classification);

Displacement measurement accuracy: ±0.5%;

Displacement resolution: 0.04μm;

Displacement indication error: within ±0.5% of the indication value;

Deformation resolution: 0.001mm;

Relative error of deformation indication value: within ±0.5%;

Large deformation measuring range: 10 ~ 800mm (if optional large deformation measuring device);

Large deformation indication error: within ±0.5% of the indication value (such as selecting a large deformation measurement device);

Large deformation measurement resolution: 0.008mm (if optional large deformation measurement device);

(3) Control parameters:

Stress control rate range: 0.005 ~ 5% FS/s;

Stress control rate accuracy: rate < 0.05%FS/s, within ±2% of the set value, rate ≥0.05%FS/s, within ±0.5% of the set value;

Strain control rate range: 0.005 ~ 5%FS/s;

The accuracy of strain control rate is within ±2% of the set value when the rate is < 0.05%FS/s, and within ±0.5% of the set value when the rate is ≥0.05%FS/s.

Displacement control rate range: 0.0001 ~ 1200mm/min;

Displacement control rate accuracy: when the rate is < 0.5mm/min, it is within ±1% of the set value; when the rate is ≥0.5mm/min, it is within ±0.2% of the set value;

(4) Machine parameters:

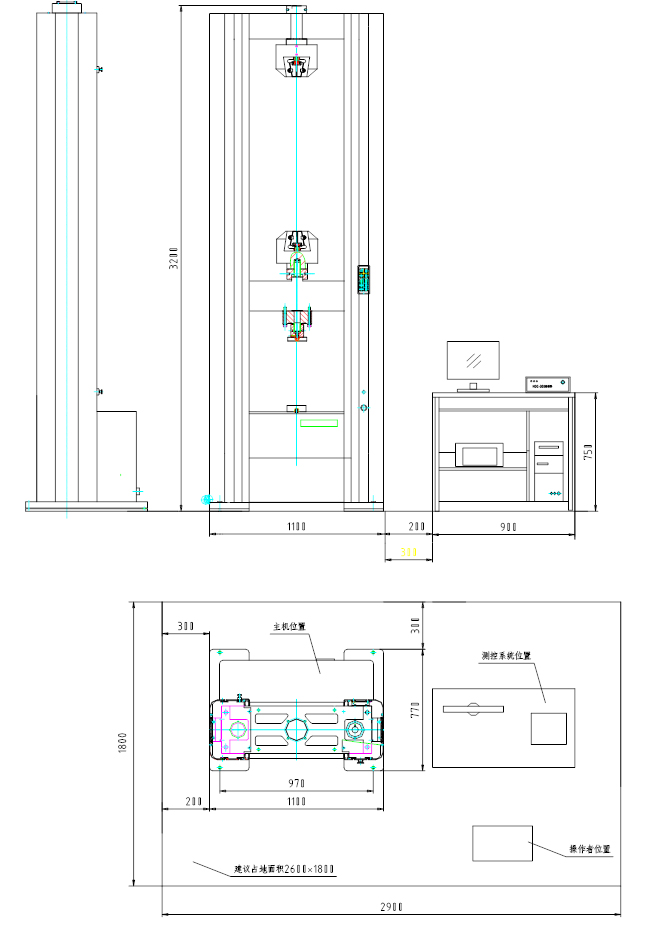

Host size (mm) : 1050×900×2250;

Host weight (kg) : 660;

Power (kW) : 2;

Power supply: single-phase, 220V;

Use environment: no vibration, no dust; Room temperature (15-25℃); Humidity <70%; No vibration, no corrosive media, no strong magnetic field interference; The voltage fluctuation of the power supply shall not exceed 10% of the rated voltage.

4. Functions and uses

This series of electronic universal testing machine is a classic practical model developed by our company, and is also the mainstream model currently produced. Is my company learning from Japanese technology, on the basis of previous generations of models, after two new upgrade design and development, the main structure and measurement and control system are greatly upgraded, the structure is more reasonable, the function is more perfect, is the industry's leading technology of a new generation of electronic universal testing machine. This series of testing machine has been through a lot of practice and continuous improvement, technology and process mature, high reliability, low failure rate, by the market and users of praise and welcome.

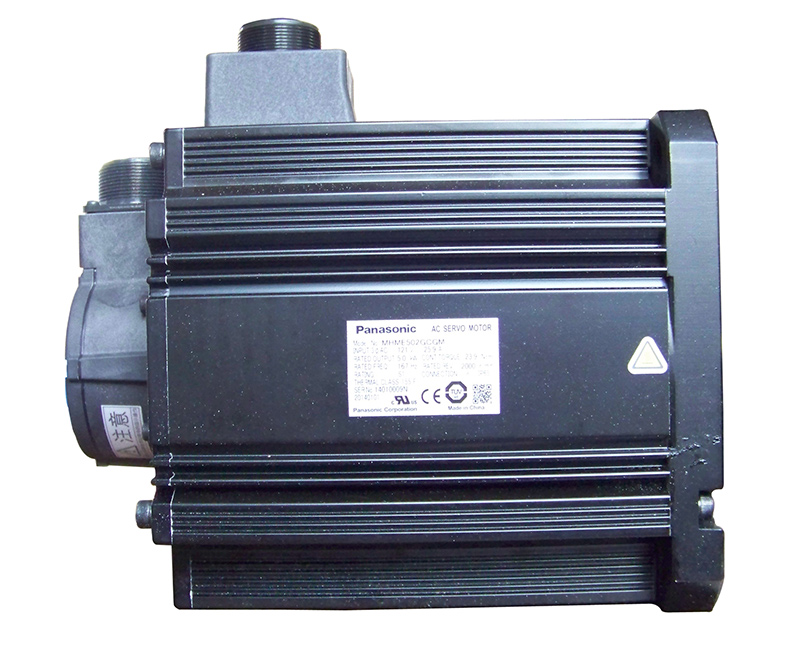

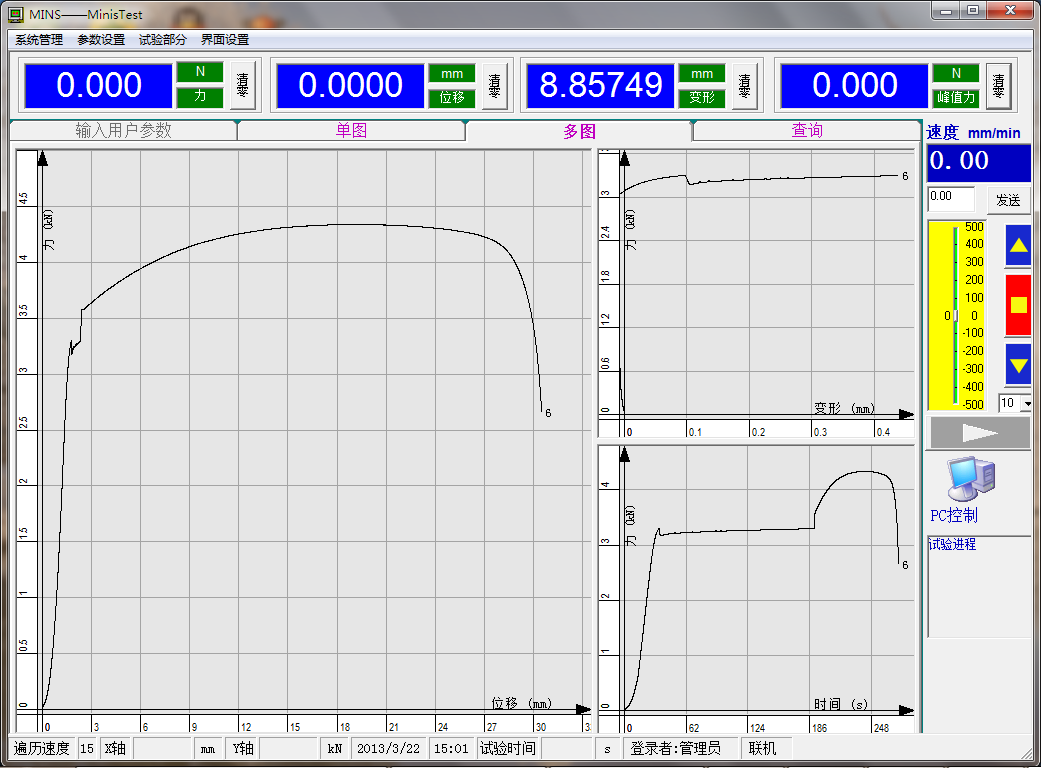

The testing machine adopts the Japanese Panasonic digital AC servo speed control system and servo motor as the driving system with high speed regulation precision and stable performance. The specially designed synchronous gear belt deceleration system and ball screw pair drive the moving beam movement of the testing machine. The control and data processing software based on database technology based on Windows operating platform realizes the screen display of test force, test force peak, cross beam displacement, sample deformation and test curve. All the test operations can be completed by mouse input on the computer screen, which has a good man-machine interface and easy operation. The independent dual-channel digital programmable amplifier realizes the real sense of physical zero adjustment, gain adjustment and test force measurement of automatic shift, zero adjustment and calibration, without any analog adjustment links, the control circuit is highly integrated, completely eliminate the potentiometer and other mechanical adjustment devices, simple structure, reliable performance. The machine can realize the closed-loop control of test force, sample deformation and beam displacement, and can realize the test of constant force, constant displacement, constant strain, constant rate load cycle and constant rate deformation cycle. The user can use the PC expert system to set the control mode of constant stress, constant strain, constant displacement, etc., and the control mode can be smoothly switched without disturbance. It can realize data processing in line with GB, ISO, JIS, ASTM, DIN and other standards, especially with good scalability, and the processing results can be stored on disk in the form of ASCII code, which provides convenience for post-processing such as reanalysis of test data, database management, and network transmission.

This series of electronic universal testing machine has powerful function and wide use. It can be used for tensile, compression, bending, shearing, stripping, tearing, extraction, ring stiffness and other mechanical properties of various metal, non-metal and composite materials. Suitable for metal materials such as wire, metal foil, metal sheet and metal bar, as well as plastic pipes, plastic profiles, waterproof coils, geotextile, wire and cable, textile, fiber, rubber, ceramics, concrete, adhesive, food and medical packaging, film, wood, paper and other non-metallic materials mechanical test. It can be widely used in machinery manufacturing, vehicle manufacturing, aerospace, petrochemical, wire and cable, paper making, textile, construction materials and other manufacturing enterprises, for quality supervision and inspection departments, research institutes and other research departments, as well as colleges and universities for teaching and demonstration.

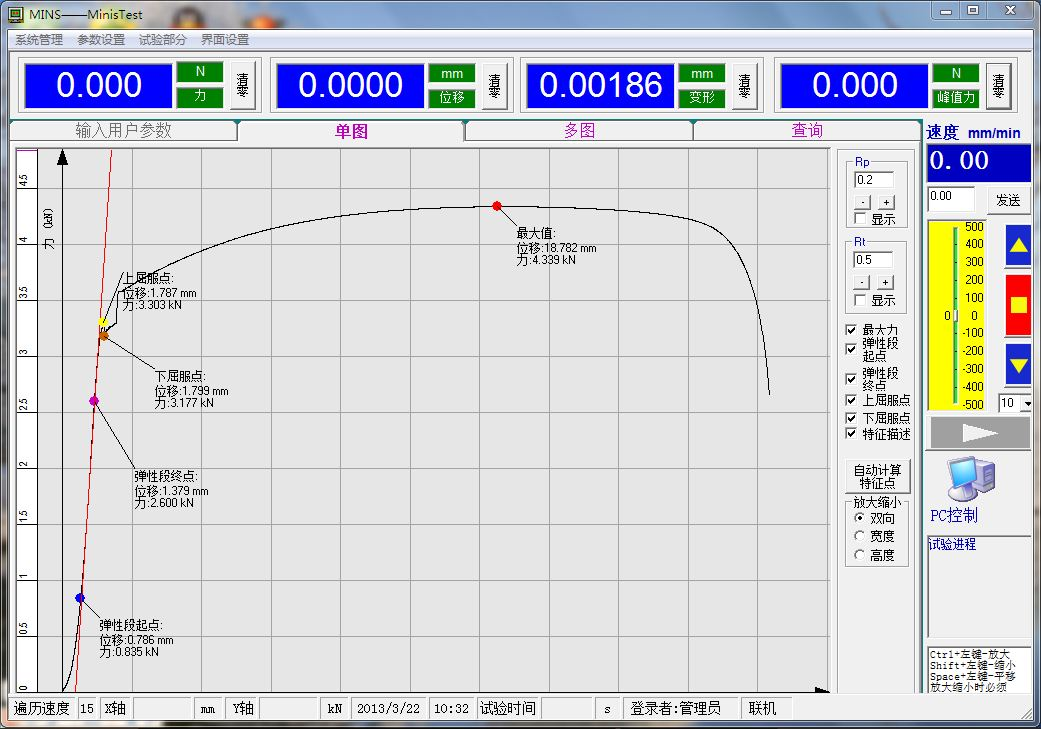

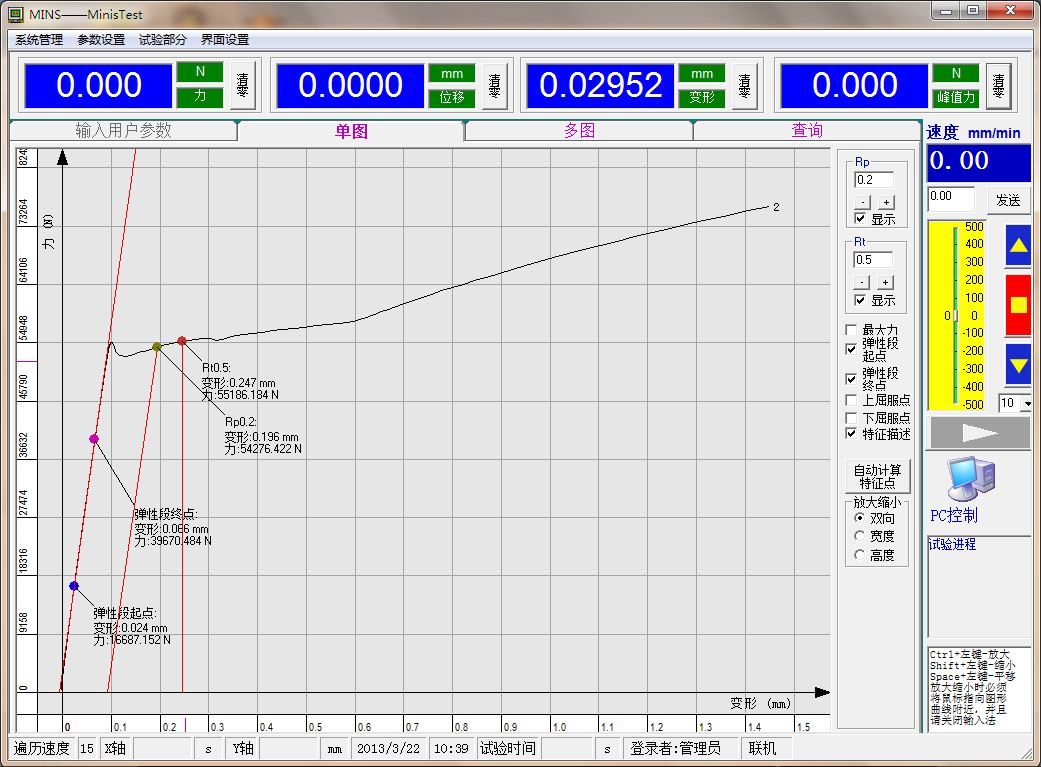

In the metal tensile test, the experimenter can clearly observe the whole test process such as low carbon steel and cast iron. By repeated loading in different curve segments, the force-displacement (deformation) curve can directly verify Hooke's law and observe the cold hardening phenomenon. For materials without obvious physical yield phenomenon, the specified non-proportional extension strength can be determined by hysteresis loop method or stepwise approximation method. In the process of compression, it is convenient to observe the compression yield phenomenon and strengthening phenomenon of low carbon steel, the compression failure process of cast iron and the fracture shape. The n and r values of the material can also be detected.

For non-metallic material test, large test space, wide speed range, and various accessory configurations can meet the testing needs of various non-metallic materials.

A variety of alternative test accessories and test standards can meet the test of different materials, to achieve a multi-purpose effect.

|

|

|

| Wire tensile test | Tensile test of sheet metal | Monofilament tensile test |

|

|

|

| Bolt tensile test | Rubber tensile test | Film tensile test |

|

|

|

| Plastic packaging tear test | 90 degree peel test | 180 degree peel test |

|

|

|

| Electronic device pull-out test | Spring compression test | Four-point bending test |

|

||

| High temperature tensile test |

5. Technical features and advantages:

1. No pollution, low noise, easy operation, high efficiency;

2. The main shell is made of aluminum alloy shell, beautiful and generous in shape;

3. The host as a whole floor vertical structure, large rigidity, stable performance, beautiful appearance;

4. Tensile and compression are realized in independent double space, avoiding the cumbersome replacement of different test accessories when using the same space;

5. The main machine structure is strong and durable. The thick ball screw and guide light screw, the thickened beam and the base, constitute a strong rigid frame, full

Testing of high strength materials;

6. The upper and lower beams and worktables of the main machine are synchronized CNC machining to ensure excellent alignment, and to ensure the sample when conducting axial tests

Under the action of load, the lateral force is least affected, and the precise stress and strain results are obtained.

7. The lead screw is precision grinding ball screw, the lead screw is made of cast copper material, wear-resistant. The lead screw pair has small friction coefficient, high transmission efficiency, high precision,

High strength;

8. The deceleration mechanism composed of reducer, synchronous tooth belt and precision ball screw pair has simple structure to ensure the synchronous movement of the lead screw

Helps to align the system;

9. High power motor with reserve power, preloaded bearing, low tension synchronous gear belt, precision ball screw pair, can be the most

The energy stored in the test process is greatly reduced, resulting in better test performance and more accurate modulus and strain values. The effect is particularly significant when testing high-strength materials, such as aviation composite materials and metal alloys;

10. The use of Japan Panasonic AC servo motor and speed control system to control the test process, high control accuracy, smooth, efficient, low noise (low speed

When there is basically no noise). And the control speed range is greatly widened (0.001-500mm/min), which is not only conducive to the low-speed test of conventional materials (metal, cement, concrete, etc.), but also conducive to the high-speed test of non-metallic materials (rubber, film, etc.), but also convenient to quickly adjust the test space when no load, saving auxiliary test time. The test speed meets the requirements of all conventional metal and non-metal materials in China.

11. Multi-specification fixture switching device, multi-accessory selection, can realize the mechanical testing of a variety of materials, giving the equipment more test functions;

12. The concentric ring and positioning pin fully ensure the upper and lower coaxiality of the test fixture, so that the sample is completely stressed in the axial direction;

13. The force value is measured by imported high-precision spoke-type load sensor with high comprehensive accuracy, high sensitivity and good repeatability. By random calibration

After the test is not affected by external force, which can ensure the accuracy of the test process and parameters;

14. Tensile, compression and other tests the sensor force direction is the same, calibration, calibration is simple and convenient;

15. Sensors of different specifications can be configured according to requirements, so that the test range is greatly widened to meet the measurement requirements of different test loads;

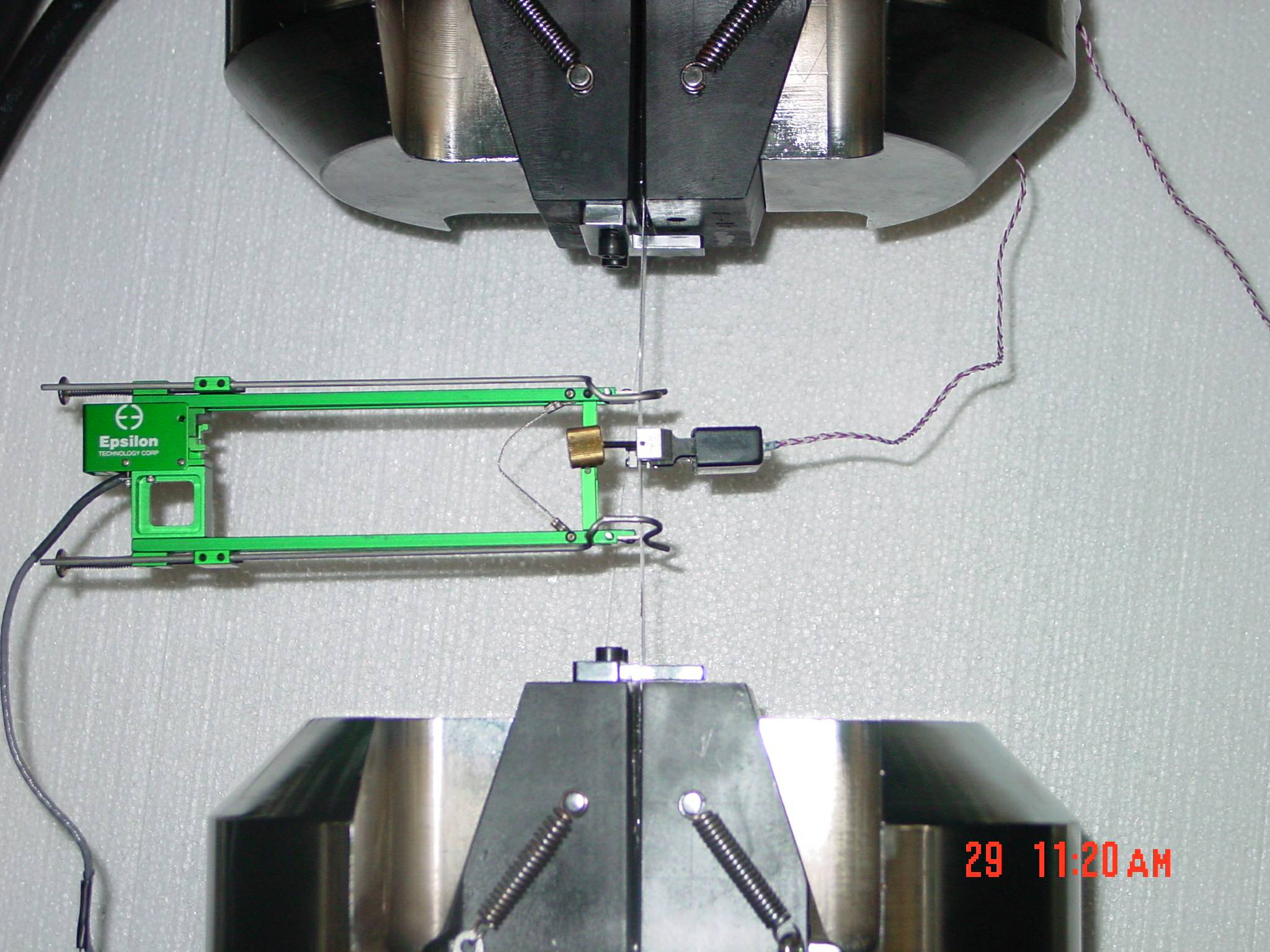

16. High precision electronic extensometer or large deformation extensometer is used for deformation measurement;

17. The displacement measurement is realized by the built-in displacement measurement system of AC servo motor;

18. The safe portable wireless remote control creatively integrates a number of functions, is very convenient to use and operate, and greatly simplifies the strong current configuration.

The use of discrete electrical components is reduced, thus effectively reducing the electrical failure rate;

19. It can realize the fast/slow lifting adjustment of the beam when the sample is installed, and the operation is flexible and can be switched at will;

20. With the function of returning to the initial position after the test, efficient and fast;

21. With perfect limit protection function and overload and overcurrent protection, test break automatic stop and other functions, reliable and safe;

22. Configure high-performance intelligent all-digital independent controller, adopt all-digital PID adjustment, and realize a hardware-based parallel sampling mode

It can realize a variety of closed-loop control modes such as constant rate stress, constant rate displacement and constant rate strain, and can realize smooth switching between different control modes without disturbance.

23. The measurement and control system is equipped with multi-function test software package and adopts VXDs high-speed data acquisition technology to realize high-speed acquisition of multi-channel data;

It can analyze and process the test results according to the requirements of different test methods, with human-computer interactive programming control function, convenient to add new test standards; It has a powerful graphical operation function, which can display the test curve and test data in real time, and has the function of curve scaling, graph magnification, interception, and cursor following display. With a complete test curve, test data storage function; With single test report output and batch test report output printing function;

24. With network interface, can achieve data networking and remote control functions;

25. The equipment is cost-effective. The quality of imported equipment, the price of domestic equipment.

6. Structure and performance:

The testing machine is composed of four parts: main engine part, power system, measurement and control system and test accessories.

(1) Host structure:

The main machine is composed of an upper beam, a moving beam and a workbench through a column and a ball screw to form a rigid floor frame structure. A tensile attachment is installed between the upper beam and the moving beam, which can be used for tensile and tearing tests on metal or non-metal material samples; Compression and bending attachments are installed between the moving beam and the workbench, which can be used to test the compression and bending of metal or non-metal material samples.

Thick ball screws and columns, thickened beams and workbenches ensure high rigidity and robustness of the frame. Fully meet the test of high-strength materials, such as aviation composite materials, metal alloys, the effect is particularly significant.

Precision integral CNC machining ensures excellent neutrality, coupled with a stable and precise rigid guide column system, ensuring that the specimen is subject to minimal lateral force under load.

(2) Power system:

|

|

| Servo motor diagram | Servo motor driver diagram |

The drive and deceleration systems are integrated under the workbench, making them compact and simple.

The testing machine adopts the AC servo speed control system with high precision and stable performance and the servo motor as the driving system, and the speed control system is composed of Taiwan Liming reducer and synchronous gear belt reducer.

The AC servo motor drives the double ball screw rotation through the reducer and synchronous gear belt reduction system, so as to drive the moving beam to move up and down to realize the sample loading.

Specially designed decelerating mechanism, symmetrical drive, more stable transmission, to ensure the synchronous movement of the lead screw, beam load balance, and help the system alignment.

(3) Measurement and control system:

It is composed of high precision load sensor, high precision electronic extensometer, servo motor built-in displacement measurement system, servo motor, special independent controller, special measurement and control software, Lenovo mainstream brand microcomputer measurement and automatic control system.

The load sensor is installed on the lower part of the moving beam and is used to measure the size of the test force.

Load sensor diagram

The AC servo motor built-in displacement measurement system is used to measure the displacement of the beam, and can also approximately replace the deformation of the sample.

For some metal materials, the testing machine is equipped with an electronic extensometer to measure the deformation of the sample. The double collet of the extensometer holds the two points of the sample marker distance and measures the separation distance between the two points of the sample marker distance in real time, that is, the deformation of the sample.

For non-metallic materials with large deformation, the displacement of the beam can be used to replace the deformation. When you need to measure the deformation accurately, you can also choose a special large deformation extensometer.

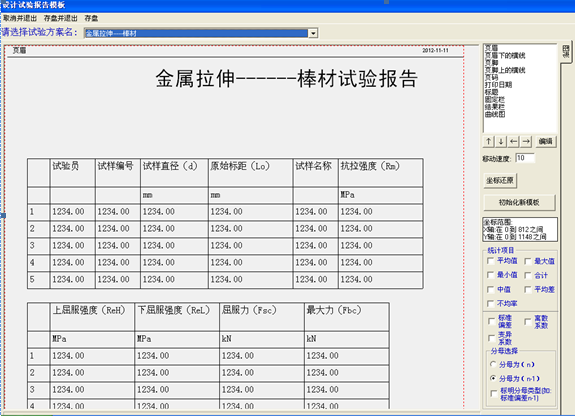

The controller and software were developed specifically for material testing machines. The software is compatible with Windows98/2000/XP/Win7 operating system. Manage test data using a standard database, integrate more than 200 national and industry test standards, and support batch testing. It can complete the real-time control, detection, data processing, result display, curve drawing, print-out, remote transmission of test force, sample deformation, displacement and other parameters.

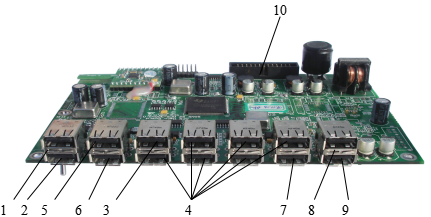

Controller: full digital three closed loop measurement control system

Independent controller diagram

Controller board diagram

1.USB slave port communication interface; 2. Analog signal sensor interface 1; 3. Analog signal sensor interface 2;

4. Analog signal sensor interface 3 ~ 8; 5. Photoelectric encoder interface 1; 6. Photoelectric encoder interface 2;

7. Inverter running direction control interface; 8. D/A analog control interface; 9. I/O input/output control interface; 10. Integrated interface.

1. Main features of the controller:

The testing machine will develop in the direction of high performance, humanization - intelligence, networking, automation, integration - high cost performance. Independent controller integrates measurement and control functions in one, dual display and dual control, independent network cable and USB dual communication control, can be switched in real time, color LCD screen can fully control the testing machine, throw away the computer, support IPAD remote monitoring, each system can complete various test operations in parallel, providing a new solution for testing machine measurement and control and data processing. It is an important part of leading the development of testing machine technology.

(electronic universal special) Independent controller is a new generation that our company has spent many years developing together with cooperative universities

Static testing machine special controller. The controller integrates powerful measurement and control functions, data processing functions, human-computer interaction functions, network functions and peripheral functions, providing a highly integrated single-system solution for the testing machine. High performance, cost-effective.

The system consists of three signal conditioning units (test force unit, displacement unit, sample deformation unit), control signal generator unit, servo motor control unit, necessary I/O interface, software system, etc.

The closed-loop control loop of the system consists of measuring sensors (load sensors, displacement sensors, deformation extensometers), servo motors, controllers (each signal conditioning unit) and servo amplifiers together to form multiple closed-loop control loops. DSP technology and neuron adaptive control algorithm are adopted to achieve full digital closed-loop control, and the most advanced PID professional control chip and multi-channel high-speed data acquisition and processing module are adopted. The mixed architecture of DSP+MCU is applied to the full digital three-closed-loop measurement control system, the resolution is not less than 1/350000FS, and the measurement process is not divided. It can realize a variety of closed-loop control modes such as constant rate test force, constant rate displacement and constant rate strain, and the control mode can be arbitrarily combined and smoothly switched.

With network interface, data networking and remote control can be realized.

Fully support GB/T 228-2010 metal tensile test standards and all kinds of non-metal tensile test standards.

2. Main function indicators of the controller:

| Function | Item Technical Index | Application |

| Sampling frequency |

load measurement: 30Hz/120Hz; Resolution: 3*10ˉ6FS Force |

torque and other measurement |

| Sampling frequency |

deformation measurement: 30Hz/120Hz; Resolution: 3*10ˉ6FS |

extender measurement |

| Displacement measurement | Capture frequency: 2MHz | servo motor position non-destructive measurement |

| Large deformation Measurement (top) | Capture frequency 200kHz | Large deformation optical code signal measurement (top) |

| Large deformation measurement (bottom) | Capture frequency 200kHz | Large deformation optical code signal measurement (top) |

| Servo motor control | PWM control frequency: 2MHz | servo motor position control |

| Digital signal input | 2 Digitallnput | upper and lower limits |

| Network cable communication | standard WALN communication protocol | and host computer communication |

| USB communication | USB2.0 specification, 480Mbps | And host computer communication |

|

Wireless Remote Control Fast Operation Control |

distance: 5m; Object Password lock | Quick operation |

| Test-D Test Software | equipment management, sample plan, test report, curve analysis | supports more than 200 test methods and standards |

| Standard Digital Measurement Channel | 3.Among them, 1 channel is a high-speed digital signal measurement channel with a frequency range of 0~2MHz, which can be directly connected to the photoelectric encoder of the servo motor; The second channel is a medium speed digital signal measurement channel with a frequency range of 0~200kMz | displacement measurement, large deformation measurement, creep measurement, etc |

| Sampling frequency | 30Hz, 120Hz. The default value is 30Hz | |

| Signal Bandwidth | 6Hz at the sampling frequency of 30Hz and 23Hz at the sampling frequency of 120Hz | |

| Resolution | 1/600000 of full scale | |

| Can expand 6 load, deformation measurement channels, can expand the hydraulic clamping control function | ||

Special measurement and control software

(electronic universal) Chinese version of the special measurement and control software has a multi-functional software package, can be selected according to the requirements of different industry users, meet the industry testing standards, with modular, open design, not only provides GB, ASTM, DIN, ISO, JIS and other standards commonly used basic test solution results, Users can also design different calculation formulas according to their own needs to solve the required results, and provide the test report template for users to design freely, in order to meet the user's personalized demand style test report. The user interface supports WindowsXP and earlier versions of the operating system, and also supports Windows7, Linux and other operating systems.

1. Online/offline: Some software functions can be run offline.

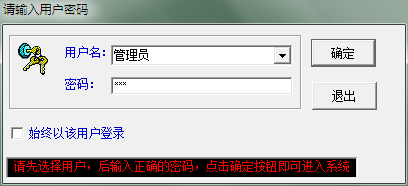

2. User management: Multi-user management and hierarchical user rights management. Users need to enter their own user name and password when logging in. Administrators have the highest rights, can manage user rights, and authorize different operators to use different software functions.

3. Device management functions: device parameter setting, device online or offline management, controller parameter setting, PID parameter online or offline adjustment, sensor direction identification, sensor calibration, sensor verification, switch and other functions.

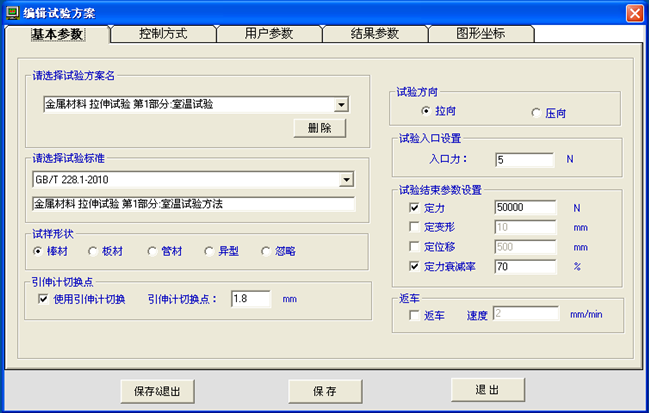

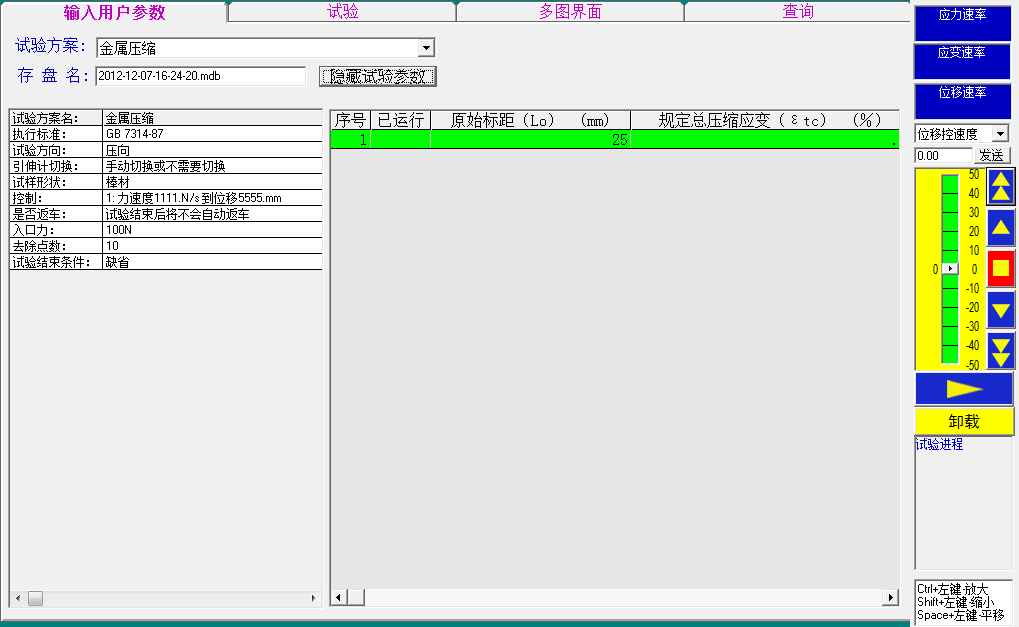

4. Test scheme: (1) In line with GB/T228-2010 fast tensile control mode; (2) The edited test scheme can be imported to other test machines for use; (3) By editing the operation plan, it can realize the combination operation of force control, displacement control, deformation control and other control methods, so as to meet the needs of any static test operation. Test parameters can be set, such as operation parameter setting, sample parameter setting, operation condition setting, test result project management. Test run management can be carried out, such as starting test run, test run process management, test state management and indicator display management.

5. Implement standard management: manage test standards and test parameters and import and export test standards; Support GB, GB/T, BS, ASTM, ISO and other standards.

6. Equipment data management: can query, delete, save the test data; Unfinished batch tests can be continued.

7. Unit parameters: Various units can be added as needed.

8. Curve management and analysis:

When the test is running, the test process is displayed in real time through single or multi-graph curves;

In the non-test running state, single or multiple test curves are displayed by querying;

Curvilinear coordinates can be preset or set online;

The test data can be viewed by curve traversal and curve playback.

The curve can be translated, scaled and other operations;

Feature points can be displayed on the curve, and feature points can be modified and saved;

Curves can be printed out independently or embedded in test reports.

9. Automatic storage of test data: automatic storage of test data to avoid loss of test data due to unexpected shutdown.

10. Test data query function: can quickly query the previously completed test data and results according to the test time, test plan and other conditions.

11. Test report: customization, preview, output/export, merge and other functions.

Query and search test data management through test data files;

Customize the content and format of the test report through the report template;

By editing formulas and result items, most test standards and test methods can be supported.

After loading one or more test data files, the test report is generated according to the report template and can be printed out.

12. Modification method: Various modifications can be made to the result items according to the requirements of the standard.

13. Encryption: You can set the life of the controller through the encryption tool.

(4) Test accessories

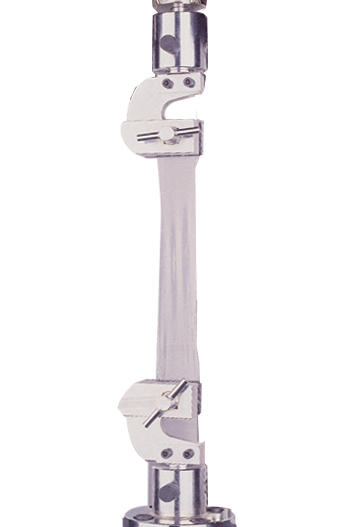

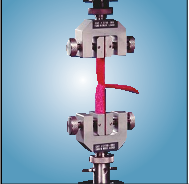

This series of electronic universal testing machine has a wide range of applications, can be used for metal materials and components testing, can also be used for a variety of non-metallic materials and finished products testing. Different tests need to use different clamping methods, therefore, we have designed a complete variety of special test accessories according to the characteristics of various test materials, users in the purchase of testing machines, must be based on the test materials, test items, standard requirements, to choose the corresponding special test accessories. (See attachment for specific fixture configuration)

Ordinary V-shaped round jaws are suitable for tensile test of metal bars;

Ordinary plate flat jaw is suitable for tensile test of metal plate;

Coarse teeth flat jaws for rubber, plastic and other non-metallic materials tensile test;

Corrugated flat jaws are used for tensile test of films and textiles.

Geotextile jaw is specially used for tensile test of geotextile;

The winding fixture can be used for tensile test of wire and wire.

The mosaic-type jaws are specially designed for clamping especially hard metal materials;

Compression accessories can be used for metal, non-metal material compressive test;

Three point bending and four point bending accessories are used for bending test of metal and non-metal materials.

6. Components and configuration:

(1) standard host part

| Item | WDW-200 |

| upper beam | 1 set (45# plate finishing) |

| moving beam | 1 set (45# plate finishing) |

| table | 1 set (45# plate finishing) |

| high precision ball screw pairs | 2 sets (screw precision grinding, tensile nut: copper) |

| columns | 2-4 |

| Ac servo motor and controller | 1 set |

| reducer system | 1 set |

| Synchronization belt | 1 set |

(2) Measurement display and control system

| Item | WDW-200 |

| High precision load sensor | 200KN 1 |

| Electronic extensometer (optional) | 1 (standard distance 50mm, deformation range 10mm) |

| controller | 1 set |

| measurement and control software | 1 set |

| computer | 1 (mainstream configuration, HP brand) |

| Printer | 1 (A4 color printer, HP brand) |

(3) Configuration test equipment

1. Wedge clamp specific: 1 set (manual clamping);

Drawing round pliers: Φ9-Φ14, Φ14-Φ20,

Stretch flat jaw: 0-7,

2. New fastener strength testing AIDS (optional)

3. Compression attachment diameter: Φ100;

4. Bolt extension accessories; (optional)

5. Three-point bending attachment (optional)

6. Four-point bending aid, (optional)

7. Adhesive strength accessories (optional)

8 Adhesive Shear AIDS (optional)

9. High and low temperature environment test box with plate testing. (optional)

(4) Random data

| Item | WDW-200 |

| Packing list | 1 copy |

| warranty certificate | 1 copy |

| factory verification certificate | 1 copy |

| Testing machine operation manual | 1 copy |

| software instruction manual | 1 copy |

| software backup CD-ROM | 1 piece |

| original random data for computer and printer | 1 set |

| Sensor, extensometer, motor, oil pump, reducer and other original random data | In pieces |

7. Expandable model (extended function):

By increasing the test space, increasing the column spacing, increasing the workbench, and installing special accessories, it can do the test of large parts, components, packaging parts, special samples, etc. With the addition of high and low temperature furnace and accessories, high and low temperature tensile test of materials can be done.

8. Service and Guarantee:

(1) Technical services

Can help users find or translate the corresponding test standards;

Can help users calculate the strength of the material, assist users to choose the right product specifications;

Can do material test for users in advance, to help select the appropriate test equipment;

At any time, we can communicate with our technical staff to help answer and solve users' problems and selection problems;

We provide complete operation manual, maintenance manual and other relevant information.

(2) Installation and debugging

After the contract comes into effect, it can provide the user with the product schematic diagram, layout plan, installation foundation diagram and electrical wiring diagram in advance, and put forward the specific requirements for water, electricity, gas, environment and other aspects, so that the user can complete the installation preparation according to the requirements;

Can help users survey, select the installation address;

After the product arrives, we send engineers to assist users in unpacking, integrity confirmation and component inventory;

Our engineers assist users in moving and installing machines;

Full commissioning and full functional testing by service engineers;

After the commissioning is completed, the product acceptance is carried out with the user, and the acceptance standard is in accordance with the relevant national verification standards;

After the final acceptance of the site, the user signs the acceptance certificate, and the product enters the free warranty period.

(3) Technical training

After the contract comes into effect, if necessary, the user can arrange operators to come to the factory to learn and test operation;

After product installation, commissioning and acceptance at the user's side, service engineers will provide on-site training to operators, explaining product principles, structure, operating procedures, usage requirements, precautions, routine maintenance, and general fault judgment and handling.

Under the guidance and supervision of the service engineer, the operator tries the operation, and the service engineer guides and corrects it in time until the operator can use it independently, completely and correctly;

When our company holds product training courses, we provide 1-2 free study places for users.

(4) after-sales service

Our company has a special customer service department and service hotline, at any time to accept user consultation and complaints;

Our company provides one-year free warranty service and lifetime maintenance service for our products. Only spare parts and travel expenses are charged outside the warranty period;

Our company implements computerized management of user files, all product debugging, maintenance, replacement of parts, fault complaints, etc. are continuously recorded in user files, dynamic monitoring and management of product running status;

After-sales service personnel will call back or visit customers from time to time every year to understand the use of products and check the operation of the equipment, and guide the maintenance and maintenance of the equipment;

After receiving the user's fault call, 4-8 hours to determine the cause of the fault and propose a solution, 24-72 hours to reach the user site, troubleshoot;

During the warranty period, when the equipment cannot be used normally due to untimely maintenance, the warranty period shall be extended correspondingly with the length of the downtime;

(5) User preparation conditions

Have a secondary school education or above, computer application skilled operator;

The user shall specify the test methods and standard rules for reference in the test;

Provide the test samples completed on this machine for product testing, factory inspection and adjustment test;

Space and foundation, power supply required for product installation;

The laboratory should be equipped with air conditioning, indoor temperature can be controlled at 15-25℃, humidity <70%;

Responsible for receiving, storing and moving products into place;

Contact local metrological department for metrological verification of equipment.

(6) Use and maintenance

Fixed, trained test personnel must be arranged to operate the product, no one else is allowed to operate;

When using the product, the operator should follow the received training and guidance to operate the correct procedure;

Operators should master the corresponding test standards in order to accurately judge the test results;

Operators must carefully read the host manual and software manual;

When testing every day, preheat the equipment for 30 minutes after starting, especially in winter when the temperature is low;

At the end of the test, shut down in the correct order and cut off all power supplies;

After each test, the tester should use a metal brush to clean the iron residue remaining on the clamping surface of the clamp, so as not to affect the next sample clamping, while protecting the shape of the clamp from damage;

The test personnel should check the integrity of the fixture regularly, clean the residue, apply anti-rust oil, etc., according to the requirements of the manual;

If the brittle material test is done, the safety net can be made to prevent the sample from breaking and flying out.

Such as self-made test auxiliary tooling, installation shall not change or damage the original main structure of the product;

If there is an abnormal situation when the testing machine is working, or the electrical appliance fails, and the start or stop button does not work, the power supply should be cut off immediately to stop the testing machine;

The lead screw and the transmission part should be lubricated regularly to prevent dry friction;

If the product is found to be faulty, contact the customer service department of our company in time to communicate, shall not be disassembled directly;

No modification of the product shall be made on its own.

(7) Product size and layout:

Wire Twisting And Winding Integrated Machine

Wire Twisting And Winding Integrated Machine

Adhesive 90-Degree Peel Strength Testing Machine

Adhesive 90-Degree Peel Strength Testing Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

CPU-1020 Cup Convex Testing Machine

CPU-1020 Cup Convex Testing Machine

Impact Testing Machine For Metal Samples

Impact Testing Machine For Metal Samples