SDW-E100 microcomputer controlled double-channel compression and torsion testing machine is a new generation microcomputer controlled measurement and control system specially designed for universities and scientific research institutes.

1. Product Introduction

SDW-E100 microcomputer controlled double-channel compression and torsion testing machine is a new generation microcomputer controlled measurement and control system specially designed for universities and scientific research institutes. The computer system controls the rotation of the servo motor through the full digital controller and the two-way speed regulating system. After the deceleration system, the precision ball screw drives the moving beam to rise and fall, and the torsion of the loading head completes the test combination requirements such as tensile, torsion, compression torsion and so on. In addition, a wide variety of test accessories are configured. It has a very broad application prospect in the mechanical properties test of metal, non-metal, composite materials and products.

At the core of the system, the two sensors and the loading system are coupled with each other and do not affect each other during the test.

2. Main technical indicators

1. Maximum test force: 20kN

3. Test force measurement range: 0.2%--100%.

4. Test force indication accuracy: better than the indication value ±0.5%

5. Test force resolution :1/500000(full ungraded or equivalent 6)

5. Beam displacement measurement accuracy: resolution higher than 0.001mm

6. Angle measurement accuracy: 0.02 degrees

7. Test speed range: 0.001-500mm /min, stepless speed regulation

8. Speed control accuracy :±1%(0.01~10mm/min);

9. Constant force, constant deformation, constant displacement control range: 0.2%-100%FS

10. Constant force, constant deformation, constant displacement control accuracy:

When the set value is <10%FS, the set value is within ±1.0%

When the set value is ≥10%FS, the set value is within ±0.1%

11. Maximum torque: 500N·m;

12. Relative error of test torque value: level 1 (±1%)

13. Test torque repeatability relative indication error: ≤1%

14. Torque resolution: 0.01N.m

15. Torsion Angle measurement range: unlimited

16. Minimum read value: 0.1°

17. Relative error of torsion Angle measurement: ±1.0%

18. Twist speed: 0.1 ~ 360°/min arbitrary setting

19 Relative error of torsional speed: within ±1.0% of the set value

20 Twist direction: forward reversal

21. Test space (customizable): A. Stretching space :900mm B. Compressed space :1000mm C. Width :500mm

22. Fixture form: according to sample

23. Power supply: single-phase,220V±10%,50Hz, power: 3kW

24. Working environment: room temperature -35 ℃, relative humidity does not exceed 80%

25. Host size :960mm×550mm×2050mm

26. Weight :580 kg

3. Solution description

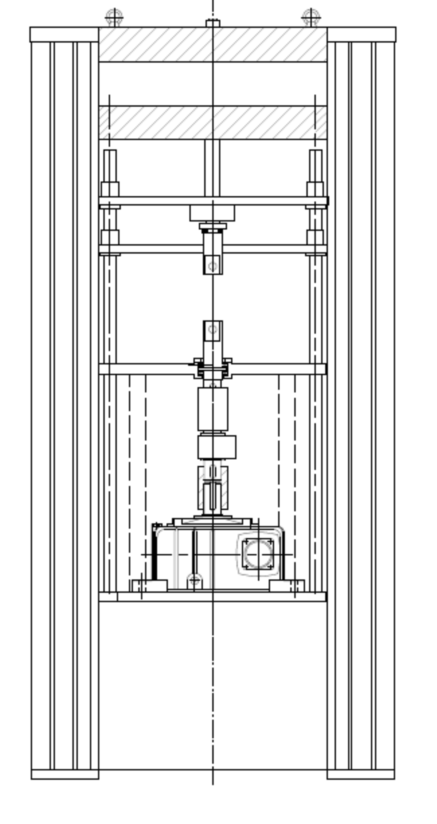

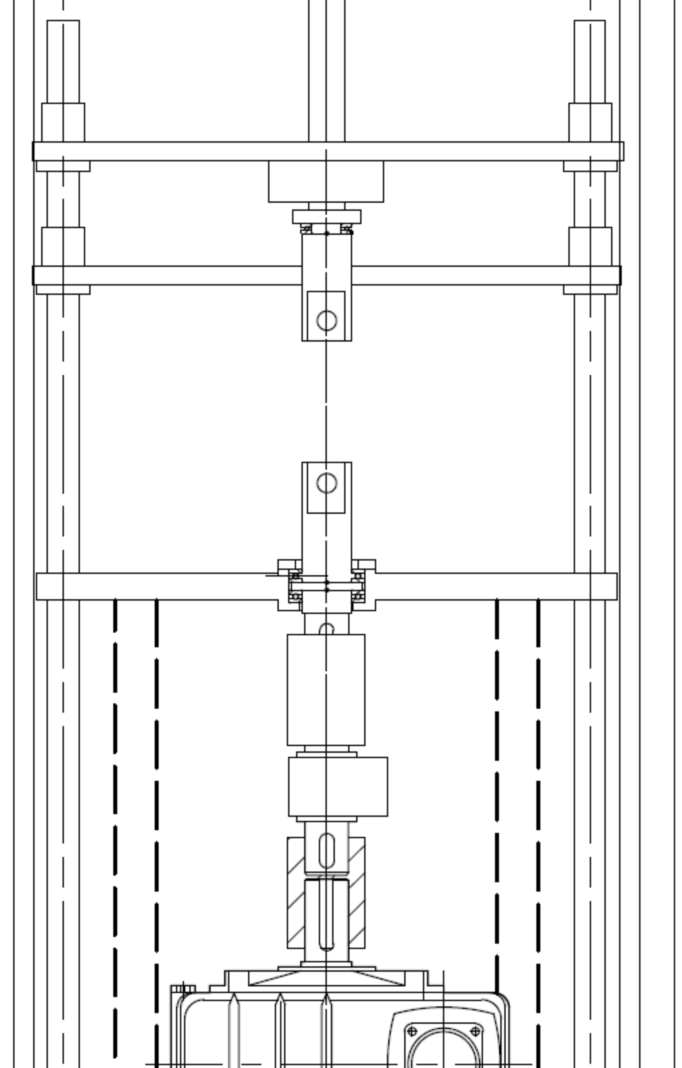

1) Host machine

1.1 The main machine adopts high steel frame structure, high strength and small deformation;

1.2 Imported high-precision ball screw, efficient and stable transmission;

1.3 The transmission part is driven by circular arc tooth synchronous belt, and there is no two-way gap in the transmission process;

1.4 AC servo motor and drive system is adopted to ensure smooth transmission, stable torque, with overcurrent, overvoltage, overload protection devices, speed ratio up to 1:100,000;

1.5 Fixture by special design, clamping firm, easy to operate, no clamp slip phenomenon;

1.6 The special process ensures the coaxiality of the testing machine and eliminates the influence of irregular samples on the sensor.

1.7NMRV high precision reducer, zero back clearance to ensure no backlash

1.8 Anti-coupling reaction frame to ensure that the two sensors do not affect each other during compression and torsion.

2) Control system

The dual-channel full digital closed-loop measurement and control system has many advanced characteristics and technical innovations, mainly reflected in:

2.1 Four closed-loop controls of test force, specimen deformation, beam displacement and test process are realized; Two loading independent operation, first twisting and then pressing, the first pressing and then twisting can be freely set, the control process can be freely changed.

2.2 The data acquisition system consists of four high-precision 24-bit A/D conversion channels. The highest resolution is 1/300000, the whole process is not divided;

2.3 Choose BB, AD, Xilinx and other original brand integrated devices, all digital design;

2.4 In line with PCI bus standards, microcomputer automatic identification and installation, to achieve "plug and test";

2.5 The electronic measurement system has no analog components such as potentiometers to ensure interchangeability and facilitate maintenance and replacement.

2.6 Parallel software replacement tooling can be used as a conventional single machine.

3. Software main function characteristic description

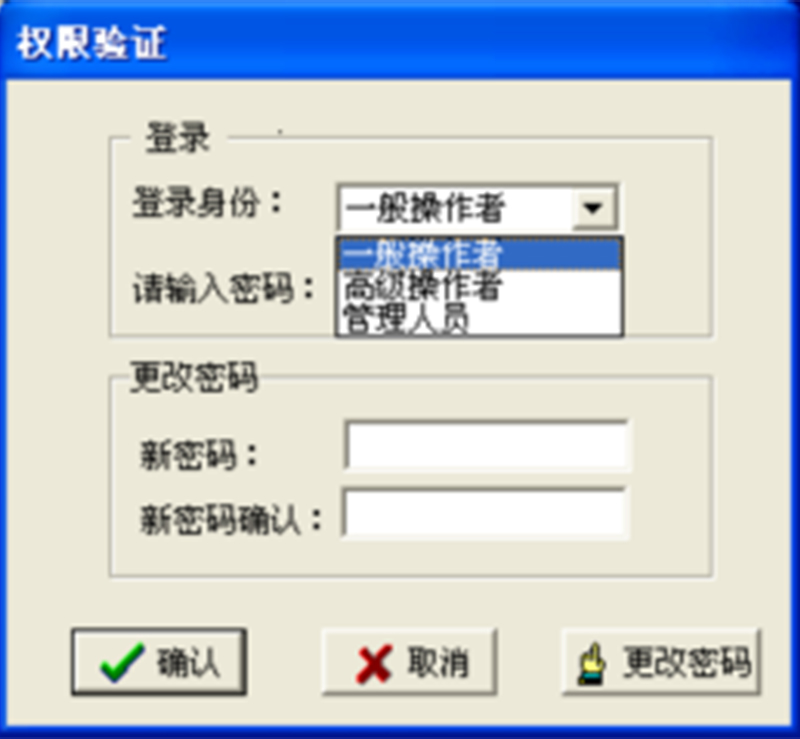

(1) By rights management, different levels of operators have different operation rights, operable menus and other contents are also different, which not only makes the ordinary operator simple, convenient and fast, but also effectively protects the system;

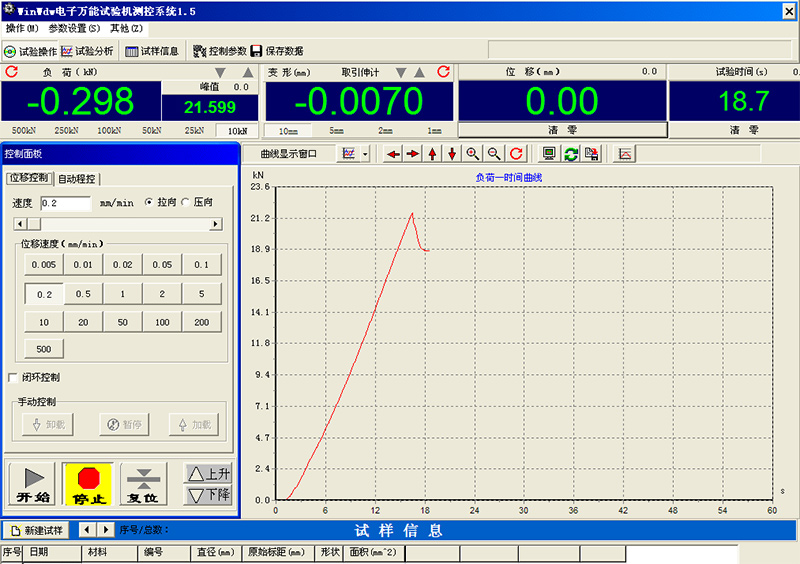

(2) Real-time measurement and display of test force and peak, displacement, deformation and other signals; It realizes real-time acquisition and control under Win7, Win10 and other win mode platforms. Accurate timing and high speed sampling are realized.

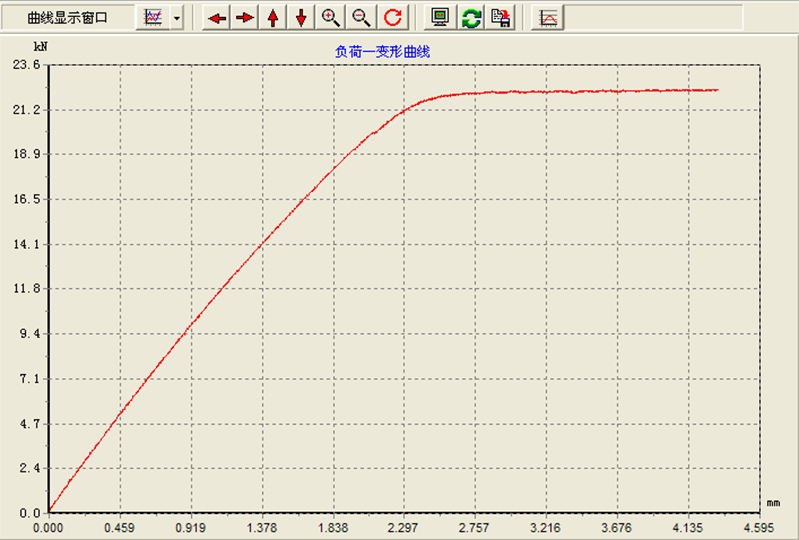

(3) Realized the real-time screen display of load-time, load-displacement, torque-angle torque-time and other test curves, which can be switched and observed at any time, and the amplification and reduction of the curve is very convenient;

(4) With the test parameters of the computer storage, setting, loading and other functions, zero, calibration and other operations are carried out from the software, each parameter can be conveniently stored and dialed in, so that a host with multiple sensors can be easily switched, and there is no number limit;

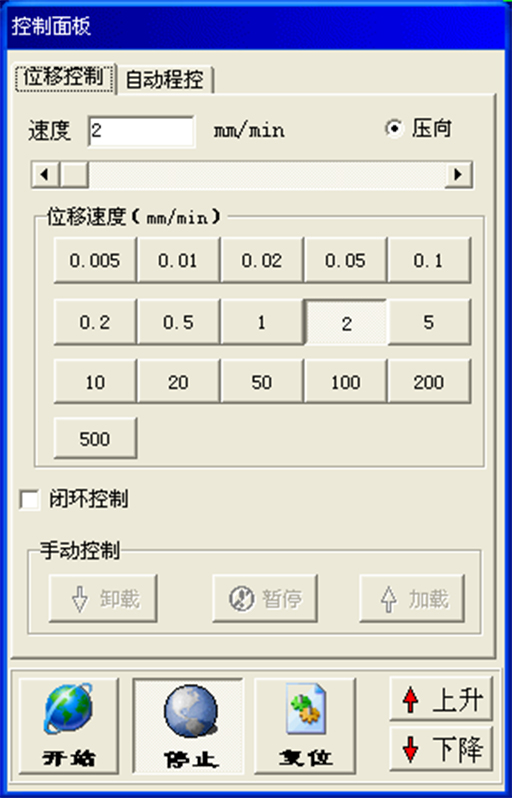

(5) Support a variety of control methods, including open loop constant speed displacement and constant speed force, constant speed stress constant speed Angle, constant speed torsion and other closed-loop control methods; The standard reference curve is given in the process of adjusting the closed-loop parameters, so that the user can actually observe the influence of each parameter on the closed-loop effect.

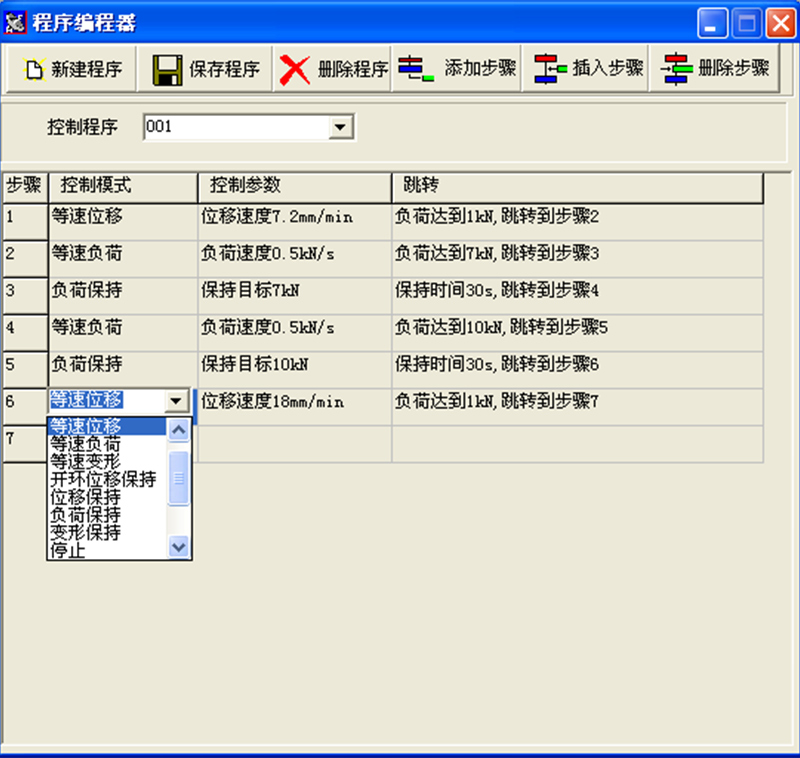

(6) With the test process control mode intelligent setting expert system, to provide professional users with automatic program control programmer. Users can flexibly combine a variety of control methods and control speeds according to the actual needs, and prepare a control program that suits their needs. The measurement and control software will automatically control the test process according to the user's setting.

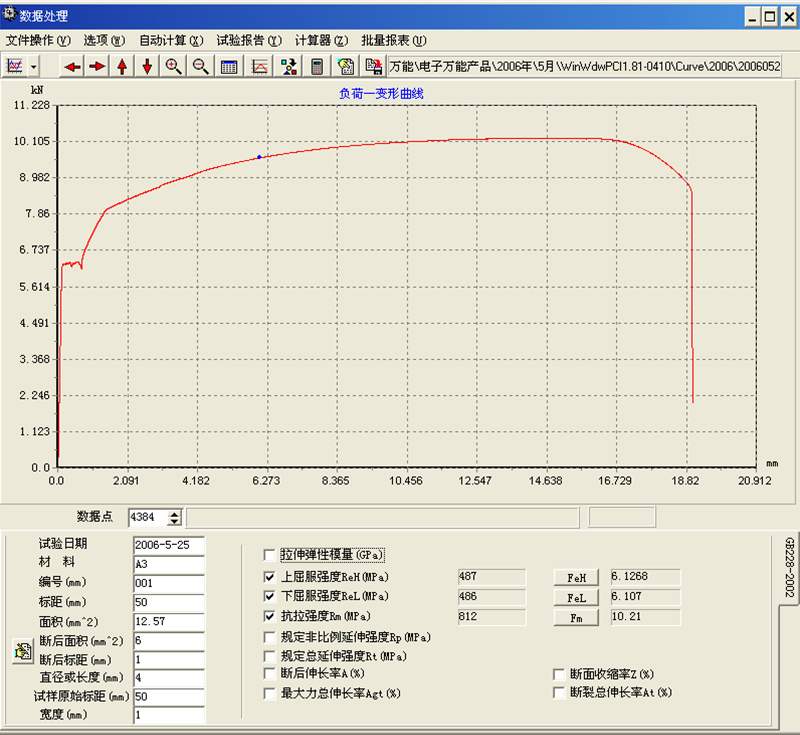

(7) Using human-computer interaction to analyze data. The processing method can meet the requirements of widely used standards, can automatically calculate elastic modulus, yield strength, non-proportional extension strength and other performance parameters, and can also manually intervene the analysis process to improve the accuracy of analysis. Other data processing can also be performed according to the standards provided by the user. Customer needs to provide specific data output requirements

(8) The test data is stored in text files to facilitate user inquiry, and the test data is reprocessed using any general business reports, word processing software, and the network transmission of data is convenient;

(9) It can record and save the data curve of the whole process of the test, and has the demonstration function to achieve the reproduction of the test curve. Curves can also be superimposed and compared to facilitate comparative analysis;

(10) The test report can be printed in the format required by the user. Users can choose the content of the report output basic information, test results and test curves to meet various needs;

(11) The digital zero adjustment and automatic calibration of the test force and deformation are realized, which is convenient for operation and improves the reliability of the machine. Various parameter system Settings are stored in file form, easy to save and restore;

(12) Can be used in Win7, Win8, Win10 and other operating systems. Test process control, beam moving speed change, parameter input and other operations can be completed by keyboard, mouse, easy to use;

(13) can automatically identify and support external point control, so that it is convenient to install the sample;

(14) With overload protection automatic stop function, and can automatically judge the sample fracture, automatic stop.

According to different user requirements, the above software functions will be increased or decreased or adjusted.

4. Software and software operation interface

(1) The software can present a Chinese window system consistent with Windows style in Windows7/8/10 user interface.

All test operations can be done on the computer screen with mouse input.

(This interface is for reference only, depending on the final software)

(2) Displacement control.

(3) Automatic program control can choose a variety of control modes.

(4) Automatic programmed intelligent expert system. Automatic process steps up to 50 steps.

(5) The software has a hierarchical management permission setting function to further ensure the safe use of the software. The software has three levels of management rights, from low to high, general operators, senior operators, management personnel, respectively by their own passwords to log in.

(6) Curve display window:

(7) Data analysis:

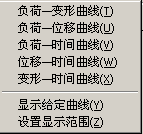

(8) Curve switch menu

5. Perform basic system configurations

1) Testing machine host (portal frame structure,)

1.1 AC servo motor and servo driver

1.2 High-precision load sensor

1.3 High-precision torque sensor

1.4 Precision ball screw pair

1.5 Precision reducer

1.6 Deceleration system (arc tooth synchronous belt drive)

2) Dual-channel programmed amplifier (resolution 1/500000)

3)Winwdw special control software

4) Photoelectric encoder

5) Accessories: customized by customers

6)HP brand computer

7) A4 inkjet printer

8) Technical data: instruction manual, software manual, certificate, packing list

Optical Cable Junction Box, Electrical Box, Optical Cable Box Sealing Performance Testing Machine

Optical Cable Junction Box, Electrical Box, Optical Cable Box Sealing Performance Testing Machine

NW-30 Bone Screw Torsion Testing Machine

NW-30 Bone Screw Torsion Testing Machine

PDS1000 Fatigue Test System V3 For Orthopedics

PDS1000 Fatigue Test System V3 For Orthopedics

PDSN3030 Compression And Torsion Fatigue Testing Machine

PDSN3030 Compression And Torsion Fatigue Testing Machine

Tooth Material Reciprocating Friction Testing Machines

Tooth Material Reciprocating Friction Testing Machines

Rotary Bending Fatigue Testing Machine

Rotary Bending Fatigue Testing Machine