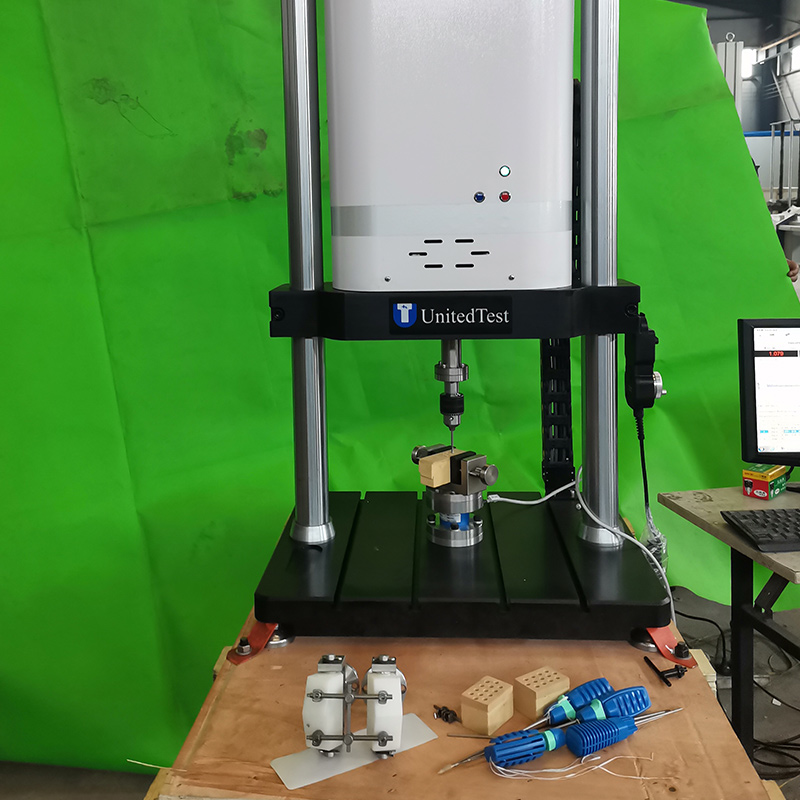

PDSN3000 Life Science Fatigue Test System Series Product introduction:

PDSN series microcomputer controlled dynamic and static fatigue test system, PDSN3000 life science fatigue test system is one of the series of dynamic fatigue loading test system products developed by our company. This series of products has the characteristics of wide output force range, high control precision, easy to use and high reliability. This series of test system in the development process of absorbing guojixianjin's electric servo cylinder drive technology, combined with the actual use of domestic users designed. The servo actuator, the selection of imported, loading frame and other key components are designed and manufactured for our company, and the controller is independently researched and developed, which greatly improves the stability and reliability of the system. The overall performance of the testing machine is equivalent to the technical level of guojixianjin products.

The test system can not only carry out dynamic high and low cycle fatigue test and program control fatigue test, but also carry out static constant rate, constant strain, constant stress control test and various conventional mechanical properties test, but also carry out fracture mechanics test. It can also test the fatigue life, crack growth, fracture toughness performance of materials or components in a broad range, safety evaluation of actual specimens, working condition simulation, etc., so it has the advantages that no other kind of testing machine can match, and is the most respected material testing equipment in the field of international fatigue mechanics research.

Because the system adopts adaptive gap-free electric servo actuator, the frequency response speed is fast, the noise is low, the energy saving and environmental protection, is very suitable for enterprises and research institutions to study and test small parts!

2. Advantages:

Linear motor technology without oil source ensures a clean test environment

The axial channel adopts Can bus control mode

High speed linear actuator

The unique driver bearing system ensures that the loading chain remains in alignment due to sample and fixture deflection or lateral forces

Suitable for dynamic and static testing of various materials and components

High dynamic performance, frequency zuida up to 50 Hz

±3000N zuida dynamic axial load

Optical encoders are used for precise digital displacement control and deformation control of samples.

Single phase power drive, no additional hydraulic oil source, cooling water, pneumatic air

Digital controller based on advanced control methods in the industry

High stiffness, precisely aligned double column loading frame with driver located on beam

Dcell advanced load sensor technology for faster testing and reduced inertia

Flexible and versatile catwalk base suitable for assembling a variety of regular/irregular fixtures and samples

The instrument design is compact and compact - the rack covers less than 0.5 m²

Main technical index

zuida test force: ±3000N;

zuida torque: 20Nm

Test force accuracy: within the range of 2%-100.%FS, each point is less than ±1.0%;

Fluctuation of dynamic indication of test force: 0.5%FS;

Actuator zuida displacement: ±50mm; Indication accuracy ±0.5%FS;

Swing motion actuator swing Angle; + 1080

Main test waveform: sine wave, square wave, triangle wave, oblique wave, etc.

Axial test frequency: 0.01-20Hz;

Axial test frequency: 0.01-5Hz;

Test space: 600*600*800

Please contact us for more information about the PDSN3000 Life Science Fatigue test system.

English

English

Español

Español

Português

Português

русский

русский

français

français

日本語

日本語

Deutsch

Deutsch

Italiano

Italiano

Nederlands

Nederlands

ไทย

ไทย

Polski

Polski

한국어

한국어

Svenska

Svenska

magyar

magyar

Malay

Malay

বাংলা

বাংলা

Dansk

Dansk

Suomi

Suomi

Pilipino

Pilipino

Gaeilge

Gaeilge

عربى

عربى

norsk

norsk

اردو

اردو

čeština

čeština

Ελληνικά

Ελληνικά

Українська

Українська

فارسی

فارسی

தமிழ்

தமிழ்

తెలుగు

తెలుగు

नेपाली

नेपाली

Burmese

Burmese

български

български

ລາວ

ລາວ

Latine

Latine

Қазақ

Қазақ

Euskal

Euskal

Azərbaycan

Azərbaycan

slovenský

slovenský

Македонски

Македонски

Lietuvos

Lietuvos

Eesti Keel

Eesti Keel

Română

Română

Slovenski

Slovenski

मराठी

मराठी

Српски

Српски

עִברִית

עִברִית

icelandic

icelandic

Беларус

Беларус

Монгол хэл

Монгол хэл

Javanese

Javanese